Description

Belt filter press Sludge Treatment Equipment

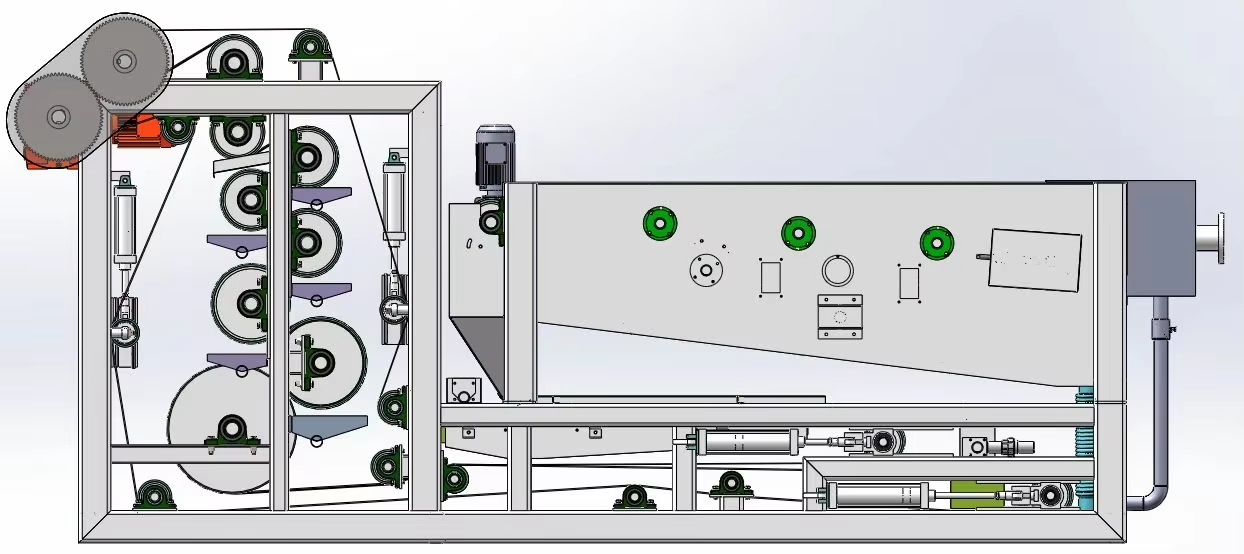

The Belt Filter Press is a highly efficient and continuous sludge dewatering equipment, specifically designed for handling various industrial and municipal sludges. Through the combined effects of gravity drainage, wedge pre-pressing, and multi-stage high-pressure squeezing, it significantly reduces sludge volume and weight, producing a cake with high solid content. Renowned for its exceptional processing capacity, stable operation, and low operating costs, this machine serves as a core component in modern sludge treatment processes.

How belt filter presses work

-

Gravity Drainage Zone: Chemically conditioned sludge is evenly distributed on the filter belt, where most free water is rapidly separated by gravity.

-

Wedge Pre-Pressing Zone: The sludge enters a gradually narrowing wedge zone, subjected to gentle and uniform pressure to enhance dewatering and form a stable sludge layer.

-

High-Pressure Squeezing Zone: The sludge is sandwiched between the upper and lower filter belts and passes through a series of S-shaped press rollers. It endures progressively increasing shear and compression forces to remove capillary and bound water, forming a dry and solid cake.

-

Cake Discharge & Belt Cleaning: The cake is automatically scraped off by doctor blades, and the filter belts are cleaned by a high-pressure washing system to restore permeability, ready for the next cycle.

Belt filter presses Technical

|

Sludge kinds |

Input concentration % |

Capacitym3/h.m |

DS capacitykg/h.m |

Moisture of cake% |

PAM consumption%(DP/DS ) |

|

Unconcentrated aerobic sludge |

0.5~1.5 |

15~30 |

150~300 |

~80(+2) |

2~5 |

|

Concentrated aerobic sludge |

2~4 |

6~12 |

200~300 |

~80(+2) |

2~5 |

|

Digested sludge |

3~6 |

7~15 |

300~400 |

<80 |

2~5 |

|

Unconcentrated primary sludge |

0.8~2.0 |

18~35 |

300~400 |

<80 |

2~5 |

|

Concentrated primary sludge |

3~5 |

6~12 |

300~400 |

≤80 |

2~5 |

|

Paper making activated sludge |

0.5~2.5 |

15~35 |

200~400 |

<78 |

3~7 |

|

Printing and dyeingmixed sludge |

1~3 |

10~25 |

180~350 |

75-85 |

3~10 |

Belt filter presses Advantage

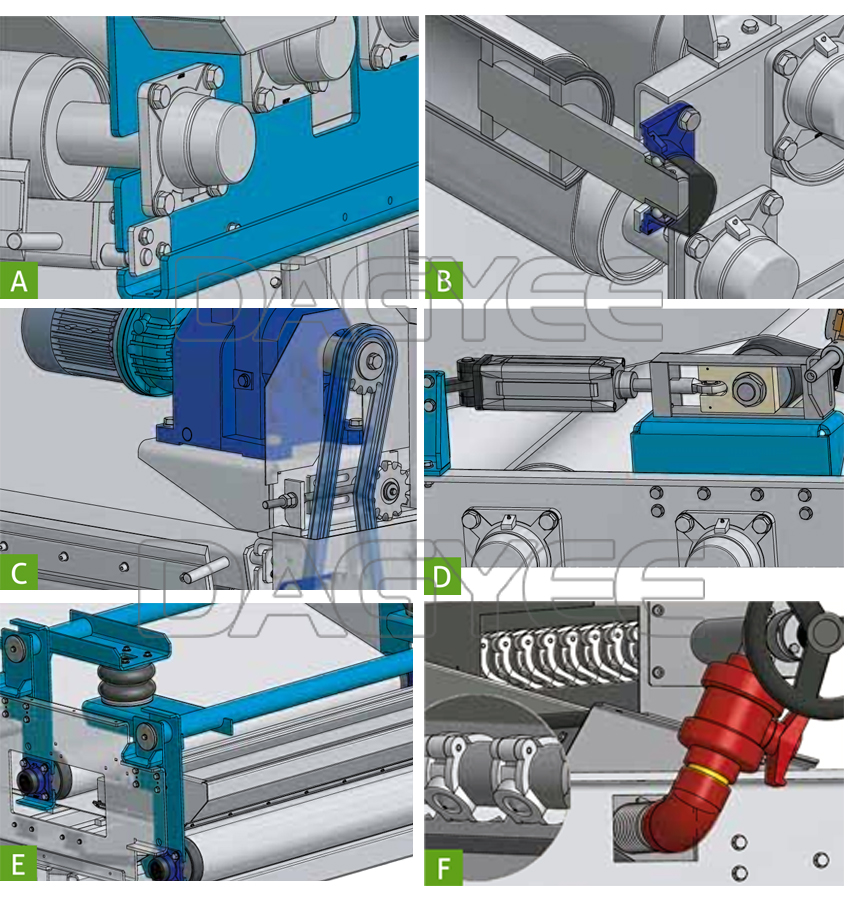

BEARING FRAME Made of two very thick carbon steel plates (on request, SST), fixed to each other by means of profiles and welded to form a stiffen perfectly levelled unit. The whole structure is protected by sand-blasting type Sa 2.5, then by a zinc-aluminium alloy hot spraying and finally covered by a layer of bicomponent polyurethanic resin. Bolts and nuts are made of SST A2 AISI 304. (Ref. A)

ROLLERS The pressing, tensioning, transmission and sludge discharge rollers are protected by a layer of 8mm of rubber. The motorized pressing roller and the trajectory correction one are coated by 8 mm. of rectified rubber layer. All the rollers are supported by ball bearings type ‘Y’ which are suitably sized and guarantee a perfect impermeability. (Ref. B

BELTS TRACTION SYSTEM Models with belts width of 800, 1200, 2000 mm.: it consists of a worm motor variator with speed manual adjustment, directly keyed to the roller; Models with belts width of 1600, 2500, 2600, 3000 mm.: it consists of an epicyclic motor variator connected to a traction roller by a toothed crown and chains protected by carters. (Ref. C)

BELTS GUIDE SYSTEM Pneumatic type with proportional action probes to keep the belts continuously centered and one upon the other. (Ref. D)

BELTS TENSION SYSTEM It consists of pneumatic jacks with air springs which keep the belts tensioned. (Ref. E)

BELTS WASHING SYSTEM It consists of spray header pipes equipped with nozzles which can be cleaned by a specia plan (Ref. F)

Belt filter presses Features

-

Continuous & Efficient Processing: Capable of 24/7 uninterrupted operation with high throughput and fast dewatering speed.

-

Multi-Stage Pressure Dewatering: Combines gravity, wedge pre-pressing, and "S"-shaped roller high-pressure dewatering to ensure low cake moisture content.

-

Intelligent Tracking System: Fully automatic pneumatic or electric tracking device ensures safe and stable belt operation, extending service life.

-

Fully Automatic Operation: Equipped with PLC and touchscreen HMI for integrated control of the entire machine, including tracking, tensioning, and washing.

-

Powerful Washing Design: Stainless steel nozzles and efficient water pathways ensure thorough belt cleaning and prevent pore clogging.

-

Robust Construction: Main structure and contact parts are made of high-quality stainless steel with anti-corrosion treatment, ensuring sturdiness and durability.

-

Low Energy Consumption Design: Low power and water consumption significantly reduce daily operating costs.

Belt filter presses Benefits

-

Outstanding Dewatering Performance: Produces cake with high solid content and significant volume reduction, drastically lowering subsequent disposal costs.

-

Excellent Operational Economy: Combines high efficiency with low energy and chemical consumption, offering the optimal treatment cost per ton of sludge.

-

High Equipment Reliability: Precision mechanical design and strict manufacturing standards ensure long-term stable operation even in harsh conditions.

-

Easy Operation & Maintenance: High level of automation reduces reliance on skilled operators; modular design simplifies daily maintenance.

Belt filter presses applicantion industries

Municipal Wastewater: Dewatering of surplus and digested sludge from urban wastewater treatment plants.

Industrial Wastewater: Dewatering of process sludge and physico-chemical/biological sludge from industries such as Pulp & Paper, Petrochemical, Pharmaceutical, Food & Beverage, Textile & Dyeing, Electroplating, and Tanning.

Other Fields: River dredging, mining tailings, coal slime dewatering, etc.