Description

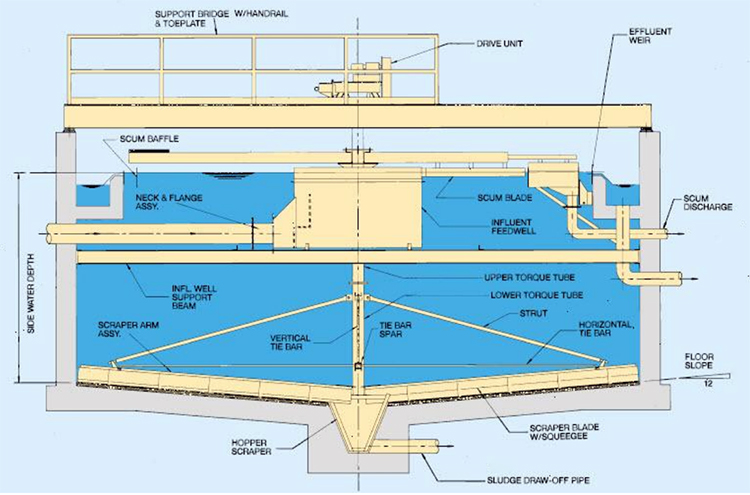

Rotating Sludge Center Transmission Mud Scraper

For non-standard equipment, there are more variable parameters, but some customers may not know the equipment well and don’t know that those are variable and optional. The editor has compiled some central drive suspension mud scrapers based on my own experience. (Enriched) machine optional parameters for your reference, personal opinion, for reference only,

The material can be quoted according to customer requirements (such as water and underwater materials, driving mechanism supporting domestic motor reducer, imported motor reducer, explosion-proof motor, etc.);

Scraper mechanism (optional);

The height of the outlet weir is adjustable;

The height of the railing can be made according to the actual requirements of the customer, the conventional one is 1.2 meters;

Walkway board (can be made of galvanized steel grating, or glass steel grating, 4mm thick checkered plate can be used);

The bottom slope of the sedimentation tank is generally ~0.1 in theory; the bottom slope of the thickening tank is generally ~0.2 in theory.

The grid bar gap of the thickener is 600mm, and the thickening gap on both sides is 300mm;

Special industries (such as smelting industry) must require customers to provide water quality load;

The distance between the scraper arm and the pool diameter (usually 10cm-20cm);

Scraper system can be optionally equipped;

| Model | DXG-12 |

| Pool diameter m | 12 |

| Water depth m | 3.6-4.4 |

| Pool depth m | 4-4.8 |

| Peripheral linear speed m/min | 1-2 |

| Drive power kw | 0.55 |

| Motor brand | SEW /NORD /GUOMAO |

| Material | Carbon steel bridge frame&transmission mechanism |

| Wetted material | SUS304/SUS316L |

Features

- Robust construction

- Self-diluting feedwell

- Enhanced polymer injection systems

- Cage and shaft lifting

Advantages

- Can develop high torque in compact units.

- Torque tube is generally more economical than a torque cage in smaller units.

- Can be installed in concrete or steel tank configurations. Generally most economical in tanks less than 50’ in diameter.

- Generally the most economical way to provide lifting of rake arms under severe torque loads.

- Lifting device option allows for heavy sludge loading

Applications

- Grind

- Thickening

- Concentrate

- Tailings

- Leach thickening

- CCD Circuits

- Acid mine drainage