Description

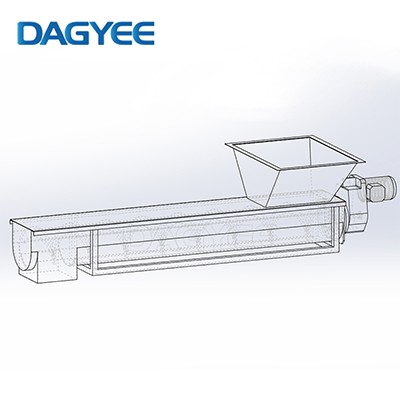

Shaftless Screw Conveyor Description

Shaftless screw conveyor is also known as anti-winding conveyor, garbage disposal conveyor, kitchen waste screw conveyor.

Shaftless screw conveyor drive device for kitchen waste: cycloidal pinwheel reducer or shaft-mounted hard-tooth surface gear reducer is used. In the design, the drive device should be located at the discharge port end as much as possible, so that the screw body is running always in tension. WLS shaftless screw conveyor casing: the casing is U-shaped, with a cover on the upper part (if necessary), and the material is stainless steel or carbon steel or glass fiber reinforced plastic. The inlet and outlet of the shaftless screw conveyor for kitchen waste: there are two kinds of square and round.

Shaftless Screw Conveyor Structure

Shaftless screw conveyor is mainly composed of shaftless screw, U-shaped spiral groove, cover plate, lining plate, inlet and outlet, discharge outlet and driving device.

Shaftless Screw Conveyor Type

Single shaftless screw conveyor screw shaft, without mixing and stirring functions.

Twin Shaftless Screw Conveyor It adopts double screw blades with mixing and stirring functions. The two screw blades rotate in opposite directions to avoid material blocking. The conveying capacity is 1.5-2 times that of a single shaft.

Inclined Shaftless Screw Conveyor mainly used for conveying materials at a small angle of 25°.

Shaftless Screw Conveyor Technical

DLS

Model

Capacities

(m3/h)

Length

Speed

Size

00

150

300

(m)

(r/min)

A(mm)

B(mm)

B0(mm)

DLS200

2

1.4

0.9

10

20

200

310

270

DLS260

3.5

2.5

1.5

10

20

260

370

340

DLS320

9

6.5

4.1

15

20

320

430

400

DLS355

11.5

7.8

5.5

20

20

355

465

435

DLS420

15

11

7.5

20

20

420

530

500

DLS500

30

25

21

20

20

500

560

680

Shaftless Screw Conveyor Benefits

- Easy to access and clean

- Low maintenance

- Modular components enable easy adaptation to various problems (results in an extremely versatile conveyor for a variety of DIFFICULT materials and a large number of applications)

- High degree of self-cleaning

Shaftless screw conveyors VS Shafted Screw Conveyors

Conveying materials

Shaftless is suitable for conveying sludge, household garbage, grid slag and other viscous, entangled materials and massive materials. It is precisely because the design of the shaftless screw conveyor without a central axis has great advantages for these materials.

The shaft screw conveyor is suitable for conveying materials: powder, small particle materials, etc. If you convey viscous

materials such as sludge, it will stick to the inner tube shaft and blades, and the conveying block materials are easy to jam.

Conveying form

Shaftless screw conveyor is suitable for: horizontal conveying, and the large inclination angle should not exceed 20°, according to the actual usage.

The shaft screw conveyor is suitable for: horizontal conveying, inclined conveying, and vertical conveying.

Conveying capacity

Due to the use of shaftless, the single-machine conveying length of the shaftless screw conveyor can reach 60 meters, and the conveying capacity is 1.5 times that of the traditional shafted screw conveyor with the same diameter

Shaftless Screw Conveyors Application

Shaftless helical (screw) conveyors are designed for handling difficult and heterogeneous materials such as municipal solid waste, screening and floating matter Substances, dehydration, thickening, conditioning sludge, packaged foods, creams or Pastes, and waste from meat, fish, fruit and vegetable processing.

Main Application areas are: wastewater treatment, sugar mill waste, fish industry, solid waste treatment, fruit and vegetable processing, beverage industry, pulp and paper, chemicals, food industry, meat processing plants, slaughterhouses, restaurants, canteens, general catering.