Description

What Is External Rotary Drum Screen

Self-cleaning wedge wire screen. Primary screening separator and removes non dissolved solid materials that could cause mechanical damage and blockages to the next treatment steps in WWTP.it is a proven fine screening technology for municipal wastewater treatment plants and many industries with several application capabilities.

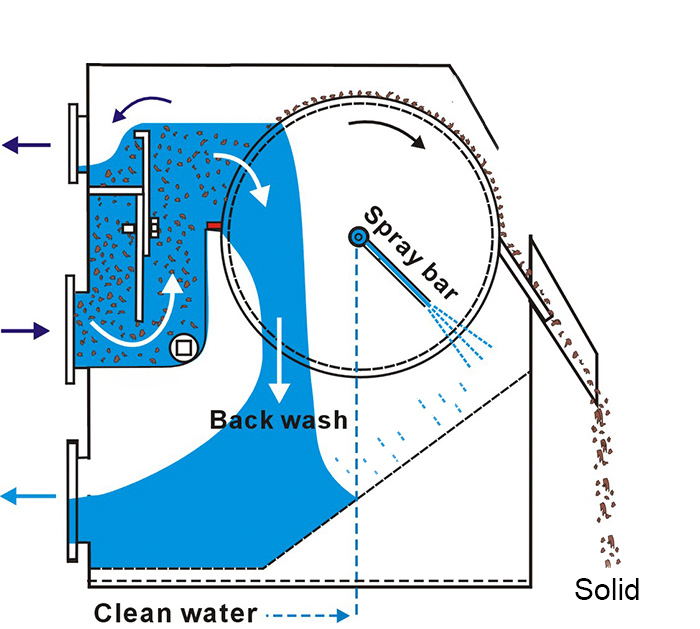

How Does External Rotary Drum Screen Work?

The discharge to be treated enters through the shaped wall located outside the screen body.Evenly distributed by the overflow channel, and overflows on the rotary drum filter. Solids will remain on the rotary drum surface as the drum rotates, and the effluent entering through the screen will perform self cleaning function when it passes through the bottom of the rotary drum again. After passing through the external scraper, the solid is detached from the rotary drum.

Technical Table

DDS

Model

Drum size

Physical Dimensions(m)

Power

Capacities(m3/h)

Effluent height

mm

L

W

H

KW

0.5mm

0.75mm

1mm

mm

DDS06/400

Ø610x400

990

1520

1650

0.37

15-20

17-20.5

25-80

500

DDS06/700

Ø610x700

1390

1520

1650

0.55

30-40

35-40

50-150

500

DDS06/1000

Ø610x1000

1690

1520

1650

0.55

45-60

50-60

75-230

500

DDS06/1300

Ø610x1300

1990

1520

1650

0.75

60-80

70-80

100-300

500

DDS06/1600

Ø610x1600

2290

1520

1650

0.75

75-100

90-100

125-350

500

DDS06/2000

Ø610x2000

2590

1520

1650

0.75

95-130

110-130

150-400

500

DDS08/2000

Ø 800x2000

2670

1730

1930

1.1

130-190

140-190

220-600

600

DDS08/2500

Ø 800x2500

3120

1750

1930

1.1

160-225

170-240

240-680

600

External Rotary Drum Screen Features

Wedge-shaped as the filter parts, No clogging;

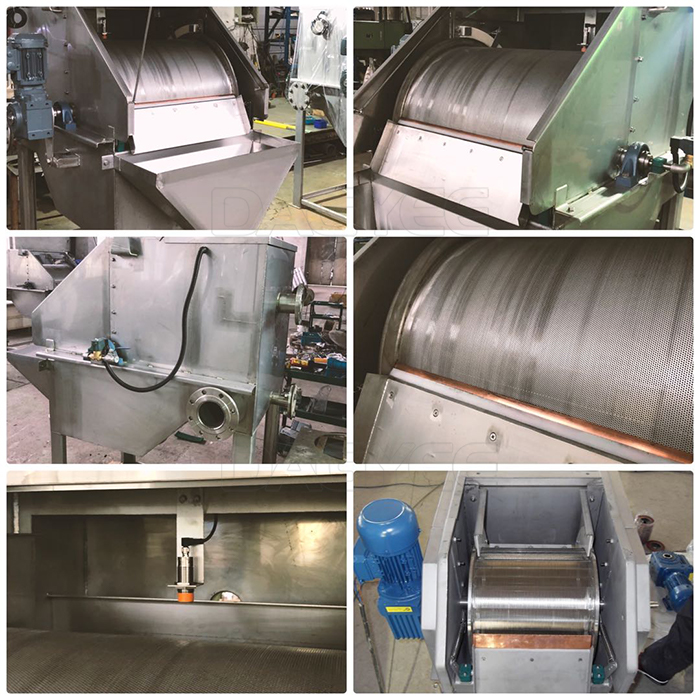

Stainless steel 304 316L;

Used for high temperature and high concentration liquid;

Drum-shaped design with a large filtering area, the floor space is small, and the energy Consumption is low;

The equipment uses the recoil nozzle to clean the clogged dirt in the grid;

Automatically and continuously running, and can automatically discharge slag;

Fully enclosed design to prevent secondary pollution during working time.

External Rotary Drum Screen Benefits

V-shaped wedge wire screen design

Built-in overflow protection

Separating and Self-Cleaning same step

Internal spray bar design

Wide range of industrial applications

Low capital and operation cost

Provide long years and trouble-free service

Automatic operation, requires little operator attention

External Rotary Drum Screen Application

Sewage treatment plantsVegetable, fruit processing industry

Sugar industry

Meat and poultry processing

Fish and shellfish processing industry

Brewing, malting and beverage industry

Horticulture industry

Industrial process water

Textile industry & laundries

Paper and pulp industry

Exhaust gas cleaning

Waste recycling industry

Bioenergy industry

Drinking water plants