Aeration Tube Installation Preparation

Aeration Tube Installation Preparation

For fixed installation, it is necessary to install a perforated cap end and a supporting frame at the end to strengthen the supporting force of the end of the aeration pipe. The advantage of this installation method is that the aeration is even.

Preparation Before Installation

After the main air pipe is installed and the air distribution pipe is connected, high-speed sulfur air must be blown in for about 10 minutes to remove the debris in the pipe. When the debris is removed, install the aeration pipe on the air distribution pipe. Foreign objects such as stones and wood chips in the treatment tank must be removed. For circular air distribution pipes, two holes need to be opened on both sides of the circular air distribution pipe, with a diameter of 15-20 mm, and the openings must be on the same axis (the maximum allowable deviation is ±0.5mm) The connection must be adjusted horizontally and vertically. Only precise positioning adjustments can ensure good operation of the aeration pipe.

Installation Of The Aeration Pipe

The installation of the aeration pipe is completed according to the installation diagram. The bolt torque should be operated with a special kilogram wrench. The maximum torque is 20Nm. The force should be even when the film is tightened. Read the installation before installation. manual. Note: When fixing the aeration pipe, do not hold the outer aeration membrane tightly to prevent the aeration membrane from being distorted. If the gasket is compressed to cause unevenness, it needs to be tightened again.

When installing the aeration pipe, it must be on a horizontal line, in a vertical position, and be applied evenly, and must not be applied on one side, so that the installation is uneven and affects the air distribution.

Use a torque clamp to fix another aeration tube.

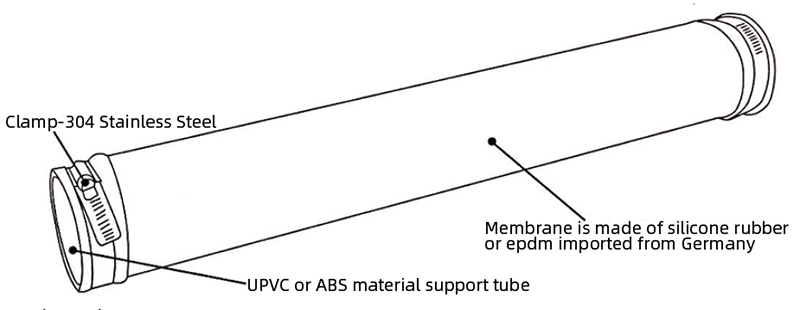

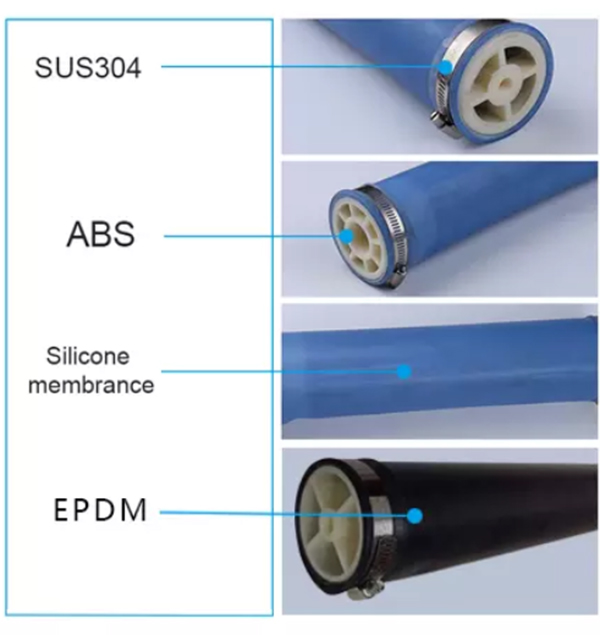

Selection Of Support Tube

The support tube used should not have any sharp corners, sharp edges and burrs, so as not to damage the aeration membrane. Only support tubes with the following dimensions can be used:

Maximum outside diameter of support tube=membrane inside diameter-1.0mm

Minimum outer diameter of support tube = inner diameter of membrane-1.5mm

Assembly Of Aeration Membrane

Put the aeration membrane on the non-porous part of the support pipe to face the air outlet opening of the support pipe, and select the adaptor, connector and seal ring that is compatible with the air distribution pipe. Special attention should be paid to ensure that the angle of the air outlet of the aeration membrane and the opening of the membrane are in the correct direction. Only single-buckle pipe clamps with a smooth inner surface are allowed. No shrink film pipe clamps are allowed. The tightening buckle of the pipe clamp must be used. It is located directly above the air outlet of the aeration membrane and the non-porous part of the membrane. When tightening the buckle, sufficient force must be used to ensure that the pipe clamp is firmly fixed and the connection is leak-free. The distance between the tightened part of the pipe clamp must be less than 2.0mm.

Start Of Operation

Trial run

After installation, pour clean water into the pool, and immediately carry out system debugging. The maximum water injection volume is 20cm above the aeration pipe. Check the air tightness of the aeration pipe and the air distribution pipe section by section. After stopping the air supply, after a while, if there is a leak due to poor sealing, air bubbles will appear. Work that may cause damage to the aeration pipe (such as painting, welding, concrete sealing, etc.) cannot be performed in the treatment pool area.

Idle time before continuous operation

If the aeration tube is not put into use immediately after the trial operation, the water level needs to be raised to a position 1m higher than the aeration tube. Please pay attention to the water evaporation factor and ensure that the water level is kept high before the equipment is finally put into operation. If the aeration pipe is heated due to exposure to sunlight, the torque needs to be rechecked before operation.

In the case of frost, the water level above the aeration pipe should be at least 10% of the lowest temperature (calculated in metric system). For example: the temperature is -20℃, and the water depth above the aeration pipe is 2m.

Operation

The water temperature must be kept between 5℃ and 30℃. Higher temperatures can also be used, but the manufacturer must be consulted before use.

Air supply

The gas supply system should be free of oil, dust, and solvents. And includes a filtration system. The gas supply system must comply with local health and safety regulations. The design value of the environmental dust filter achieves a filtering effect of 90%, which meets the requirements of EN779, filtering grade G4. The air temperature at the inlet cannot be higher than 80°C, and the air temperature can be increased only with the permission of the manufacturer. In the operation of the aeration pipe, the air flow rate should be between 2-12 m³/h.

Free time

If the aeration tube is at the lowest air delivery rate for a long time, it needs to be ventilated at the maximum air delivery rate every week, which is about 20 minutes.

Maintenance/cleaning

When the treatment tank is emptied, be careful not to let the sediment on the aeration pipe dry, that is, the aeration pipe must be cleaned immediately. The drying of the sediment will affect the performance of the aeration pipe. Sometimes, some steps will produce precipitation, please remove it in the initial stage. Therefore, it is necessary to regularly check such deposits from the very beginning, and specify the corresponding cleaning cycle. You can use the mechanical cleaning method of high-pressure water jet aeration pipes, and the aeration pipe needs 10cm of water. When cleaning, the air delivery volume should be 4 to 5m³/h.

Measurement of oxygen transfer rate Before measuring the oxygen transfer rate, it is necessary to ventilate for at least 48 hours (ventilation rate is 8mN3/h.ma) to ensure that the aeration tube can operate normally. Otherwise, please follow the contents of the latest version ATVM209 of the wastewater purification regulations.

Ashely

Wuxi Dajiang Environmental Technology Co., Ltd.

T:+86051085100889

M:+8613961861780

Whatsapp/Facebook : 8613961861780

www. wastewatermachinery.com