Description

Mechanical Fine Screen Description

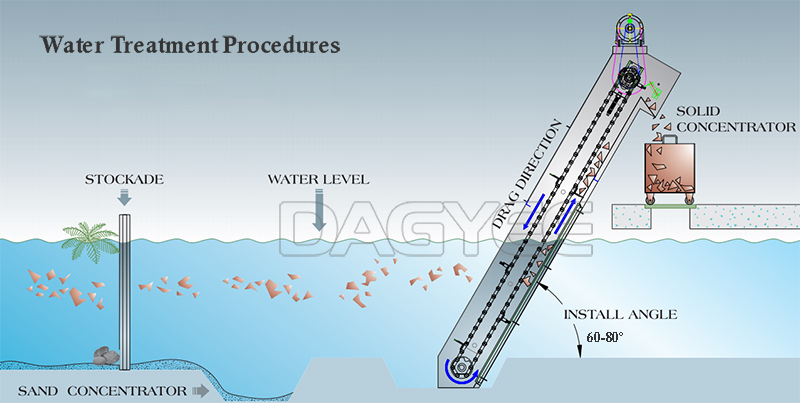

The fine grid decontamination machine is a special equipment for water treatment that can continuously and automatically intercept and remove various shapes of debris in the fluid. It can be widely used in urban sewage treatment. It can also be used as a front-stage screening equipment in the wastewater treatment process of textile, food processing, papermaking, leather and other industries. It is one of the solid-liquid screening equipment in my country at present.

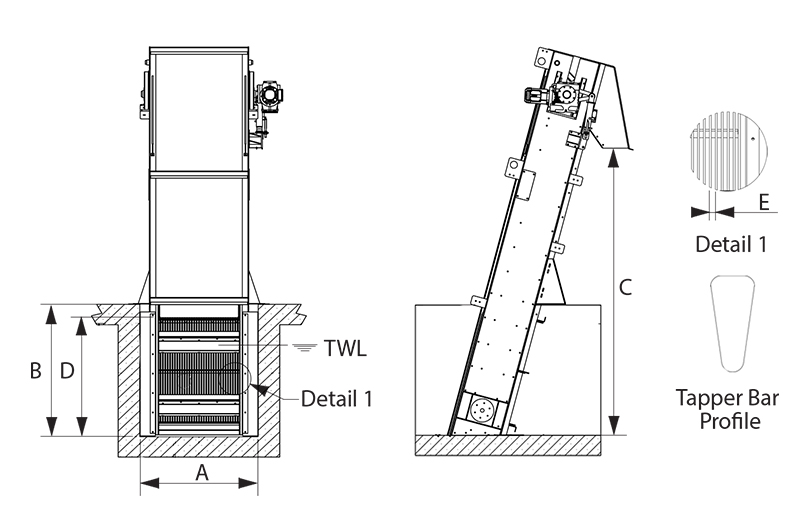

The rotary screen is installed at the inlet of pump station or water treatment system. It is composed of pedestal, specific plough shaped tines,rake plate, elevator chain and motor reducer units etc. It is assembled into different spacing according to different flow rate.The rake plate ,which is fixed in the elevator chain,starts clockwise movement under the drive of the driving device, hooking residue from down to up together with the elevator chain. Under the effect of steering guide and guiding wheel, residue gets discharged by gravity while the rake plate reached the top of screen. The rake tines moved to the bottom of the equipment and starts to work for another round,residue moves continuously.

Mechanical Fine Screen Composition

Parts of the fine grille of the inner inflow mesh plate frame;

Drive System;

Stencil System;

backwash system;

Division system and Electronic control system;

The geared motor drives the sprocket to rotate. The sprocket drives the mesh plate to rotate continuously; the sewage enters the grille from the water inlet, and passes through the mesh plate to overspeed. The water flows to the outside of the screen plate, and the dirt is left on the inner surface of the same plate. With the continuous rotation of the screen plate, it helps to the original part: the backwash system flushes the outside of the screen plate, and the dirt is washed to the receiving channel under the action of the flushing water. Feel free to check the flushing water from the well to the sewage outlet.

Mechanical Fine Screen Parameter

Stencil width (mm): 900-3000

Aperture (mm): 2-6

Power (KW): 1.5-4.0

Applicable pool depth (m): 2-15

Applicable pool width (m): ≥1.5

Flushing water pressure (bar): ≥3.0

Capture rate: 80-90%

Processing capacity of a single unit (10,000 tons/day): 4-15

Mechanical Fine Screen Advantage

High-strength mechanical structure design, the continuous operation of the equipment is more reliable and guaranteed;

The forced continuous filtration design of the grid prevents substances such as grid slag from flowing to the rear of the grid;

Guaranteed higher filtration efficiency;

The screen slag and other substances retained on the filter plate are washed by the nozzle to obtain the cleaning effect;

The vertical installation saves space, and the renovation does not need to change the original civil construction, which has better cost performance;

The fully sealed structure of the grille effectively controls the release of odor;

Compared with other products, it can filter more water with less head loss.

Mechanical Fine Screen Options

Alternative screen types and sizes

Material 304 L / 316 L SS

Alternative voltage and frequency

Alternative degree of motor protection

Control panel

Mechanical Fine Screen Application

It is a high-efficiency fine grille decontamination equipment that combines pollution blocking and decontamination.

It is suitable for large, medium and small pump stations as fine grilles to intercept and remove floating objects in the water, such as: weeds, paper, cigarette butts, melon seeds, fibers, hair, etc.

This model has a high dirt capture rate , the effective implementation of the subsequent treatment process.