Description

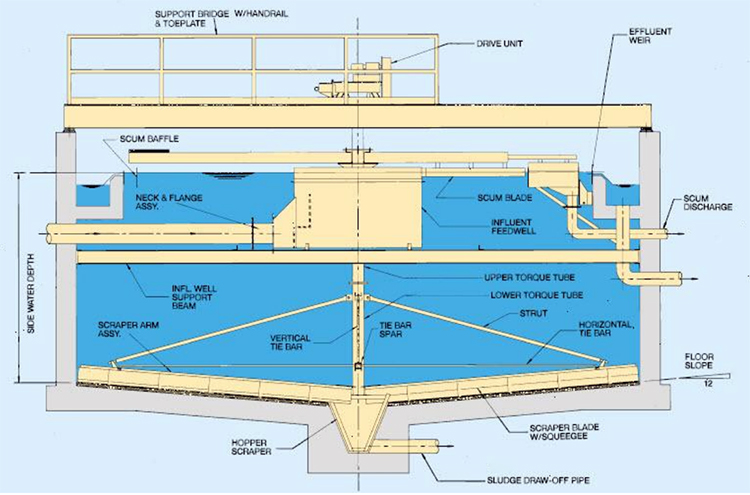

Full Bridge Clarifier Center Drive Mud Scraper

| Model | DXG-6 |

| Pool diameter m | 6 |

| Water depth m | 3-3.6 |

| Pool depth m | 3.4-4 |

| Peripheral linear speed m/min | 1-3 |

| Drive power kw | 0.55 |

| Motor brand | SEW /NORD /GUOMAO |

| Material | Carbon steel bridge frame&transmission mechanism |

| Wetted material | SUS304/SUS316L |

When the central drive suspension scraper is in operation, the drive device installed on the working bridge drives the suspension shaft to rotate. When the drive shaft rotates, the suspension scraper arms on both sides rotate around the center axis of the pool. The scrapers installed on the scraper arms on both sides The mud plate scrapes the sludge deposited on the bottom of the pool to the mud collecting pit in the center of the pool while rotating with the scraper arm. At the same time, the scum on the liquid surface is concentrated in the tapered area formed by the slag scraper and the surrounding slag baffle, and is scraped by the scum to the slag collecting bucket and discharged out of the tank.

The working principle of the thickener is similar to that of the sludge scraper. The difference is that the thickener is provided with a vertical cross-arranged thickening grid on the scraper arm. The grid rotates with the scraper arm to escape free water from the sludge. Provide channels to improve the concentration efficiency of the sludge layer in the sedimentation tank.

Advantages

- Can develop high torque in compact units.

- Torque tube is generally more economical than a torque cage in smaller units.

- Can be installed in concrete or steel tank configurations. Generally most economical in tanks less than 50’ in diameter.

- Generally the most economical way to provide lifting of rake arms under severe torque loads.

- Lifting device option allows for heavy sludge loading

Applications

- Grind

- Thickening

- Concentrate

- Tailings

- Leach thickening

- CCD Circuits

- Acid mine drainage