Description

What Is DAF Dissolved air flotation

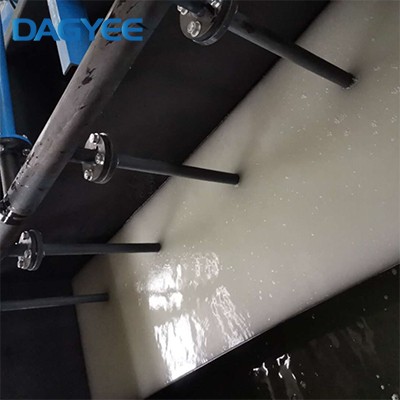

Dagyee DAF System proactively promotes solid/liquid separation providing better contaminant removal, more efficient chem usage and drier sludge – using a much smaller footprint than conventional DAFs.

The DAF System is often referred to as a 'DAF on Steroids'. However, as opposed to DAF's that require significant retention time and rely on the old-school particle collision process to float solids, the DAF System injects air into 100% of the waste stream while pushing water through a series of hydrocyclones under controlled pressure, removing up to 100% of TSS & FOG.

Chemicals are uncoiled in the Heads availing more than 2x the charge sites resulting in a higher rate of contaminant removal. Since separation occurs in the Heads, large tight flocs float and are skimmed off the tank into a sludge hopper. Drier sludge ensues as the air dissipates and chemicals recoil, to naturally dewater the flocs. Costs are reduced due to lower chemical, sludge handling and building costs.

As a waste water process, DAGYEE DAF Dissolved air flotation is widely used in sewage treatment and water purification engineering. DAF Dissolved air flotation is suitable for :

- Increase effluent recycling and fresh water reusing in paper and pulp

- Removal of heavy metal ions

- Separation of oil refinery effluent

- Removal of tannery wastewater

- Removal of chromaticity and impurities in printing and dyeing wastewater

- Solid-liquid separation of sewage and membrane after all kinds of bio-treatment

- Sludge concentration (capacity: 20%~ 30%, except the dedicated device which can be designed according to the requirements)

Why Choose DAF Dissolved Air Flotation

- Total suspended solids (TSS) reduced by up to 97

- Chemical oxygen demand (COD) removal rate of up to 60-80%

- Integrated sludge hopper for easy removal of solid deposits .

- The DAF area provides a static space for the formation of the float.

- Heavy-duty, fully protected, counter-current surface separator that removes surface float

DAF Dissolved Air Flotation Process

DAGYEE DAF Dissolved Air Flotation Advantage

-

The most effective white water / recycling design. Large effective settling area

-

With optional chemical processing stage improved separation efficiency

-

Compact clarifier and reaction cell design surface loading up to 15m3/m2hr

-

Rugged design for easy understanding, operation and maintenance

-

Carbon steel and stainless steel body material design, the lowest cost of ownership

|

DAF |

Qmax. |

PhysicalDimensions(m) |

Weight |

Operating |

Power(kw) |

||||

|

L/L1 |

W/W1 |

H/H1 |

Refluxpump |

Air compressor |

Skimmer |

||||

|

DAF-002 |

2 |

3.4/2.5 |

2.4/1.16 |

2.2/1.7 |

1300 |

4000 |

0.75 |

0.55 |

0.2 |

|

DAF-003 |

3 |

3.7/2.8 |

2.4/1.16 |

2.2/1.7 |

1500 |

5000 |

0.75 |

0.55 |

0.2 |

|

DAF-005 |

5 |

4/3 |

2.4/1.16 |

2.2/1.7 |

1600 |

7000 |

1.1 |

0.55 |

0.2 |

|

DAF-010 |

10 |

4.65/3.8 |

2.7/1.36 |

2.4/1.9 |

2000 |

12000 |

1.5 |

0.55 |

0.2 |

|

DAF-015 |

15 |

5.6/4.5 |

2.9/1.66 |

2.5/2 |

2200 |

18000 |

2.2 |

0.75 |

0.2 |

|

DAF-020 |

20 |

5.9/4.8 |

3.2/1.96 |

2.5/2 |

3000 |

22000 |

3 |

0.75 |

0.2 |

|

DAF-030 |

30 |

6.8/5.5 |

3.2/2.16 |

2.7/2.2 |

3800 |

32000 |

3 |

0.75 |

0.4 |

|

DAF-040 |

40 |

8/6.7 |

3.6/2.6 |

2.7/2.2 |

5000 |

45000 |

5.5 |

0.75 |

0.4 |

|

DAF-050 |

50 |

8.4/7 |

3.6/2.6 |

2.7/2.2 |

5500 |

55000 |

7.5 |

0.75 |

0.4 |

|

DAF-060 |

60 |

9.9/8.4 |

3.8/2.8 |

2.9/2.4 |

6000 |

66000 |

7.5 |

1.5 |

0.4 |

|

DAF-070 |

70 |

10.4/9 |

3.8/2.8 |

2.9/2.4 |

6500 |

75000 |

11 |

1.5 |

0.4 |

|

DAF-080 |

80 |

10.8/9.4 |

4/3 |

2.9/2.4 |

7500 |

100000 |

11 |

1.5 |

0.4 |

|

DAF-100 |

100 |

12.1/10.6 |

4.2/3.2 |

2.9/2.4 |

9000 |

110000 |

15 |

1.5 |

0.4 |

|

DAF-120 |

120 |

12.5/11.4 |

4.4/3.4 |

2.9/2.4 |

10000 |

130000 |

15 |

1.5 |

0.4 |

DAF Dissolved Air Flotation Application

| Slaughterhouses |

| Meat processing and pack- ing |

| Fish processing Dairies |

| Convenience food production |

| Margarine production Oil and fat refineries Canneries |

| Industrial kitchens and can- teens |

| Fast food providers Soap works Cosmetics industry Textile industry Chemical industry |

| Petrochemical industry Iron and steel industry Metal processing Galvanizing, electroplating Land remediation |