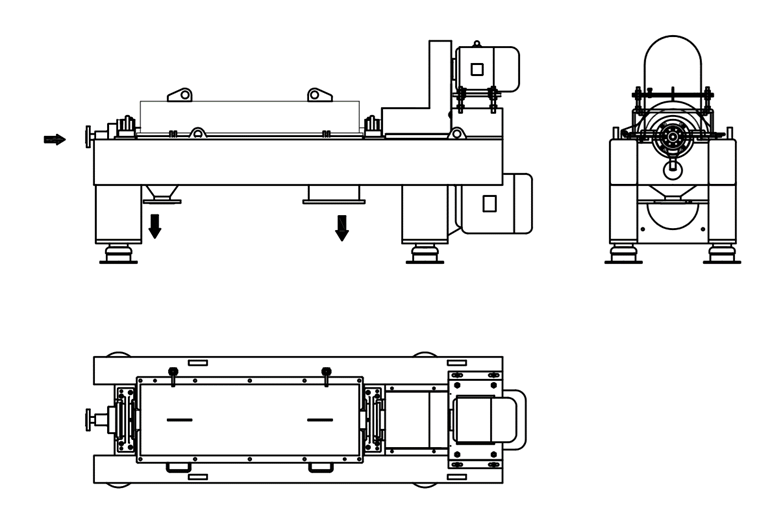

Description

2 Phase Decanter Centrifuges Description

The LW decanter separator is suitable for plant oil,( such as palm oil, coconut oil, olive oil separation ,) animal oil(such as fish oil, restaurant garbage ect) fish meal, coal tar dehydration and slag, adapted to the different viscosity and water content in coal tar separation (emulsion), after separating the tar reach national standard.

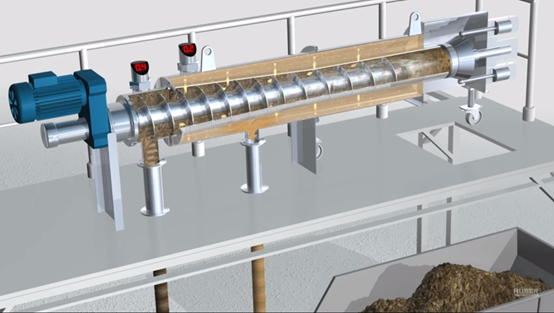

Decanters with slow rotation speed are normally based on horizontal separation technology. Decanters ensure optimum separation efficiency in the case of suspensions with a very high proportion of solids. They are also used for the extraction of constituents from liquids and for concentrating, dewatering and classifying solids.

2 Phase Decanter Centrifuges Model

| Model |

Drum diameter

mm

|

Length

mm

|

Maximum speed

rpm

|

Hightest separation

factor g

|

Mixture capacity

m3/h

|

Motor Power

Kw

|

| LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 | 11/5.5 |

| LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 | 18.5/5.5 |

| LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 | 22/7.5 |

| LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 | 22/7.5 |

| LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 | 22/7.5 |

| LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 | 30/7.5 |

| LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 | 30/7.5 |

| LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 | 45/15 |

| LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 | 55/18.5 |

| LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 | 55/90 |

| LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 | 75/90 |

| LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 | 90/132 |

| LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 | 90/132 |

| LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 | 132/200 |

2 Phase Decanter Centrifuges Technical

All contact parts can be made by SS304/SS316L/Duplex Steel 2205 Automatic adjustment of differential speed via VFD,Siemens PLC Spiral :

Surfacing welding tungsten carbide grinding

Two motor drive

Approximately 80 to 90% of the oil is recovered

Low labor costs due to continuous and automatic operation

Highest g-force for higher solids output

Belts for both primary motor and secondary

NSK/SKF Bearing

2 Phase Decanter Centrifuges Features

Low noise, its vibration intensity is less than 4.5, and the running noise of the machine is less than 85dB (A).

High Speed up to 3600RPM & Variable Speed by frequency converter

The main body of the decanter centrifuge made from stainless stee: SS304/SS316/Titanium Alloy

The screw propeller made from stainless steel (SS304/SS316) protected by Tungsten carbide alloy or Ceramic

Solids discharge stainless steel protected by high-chromium iron

Solids Liquid separation system package available

Germany FAG/SKF brand bearings

Eletrical Components: SIEMENS/Schneider/ABB

All the seals of the machine are imported , adopting the Taiwan TTK brand

2 Phase Decanter Centrifuges Application

Food: Fruit and Vegetable juices, Starch, Protein, Molasses, Stillage

Oils and Fats: Fish oil, Gelatine

Environmental protection/Recycling: Drilling mud, Industrial wastewater, Municipal wastewater