Description

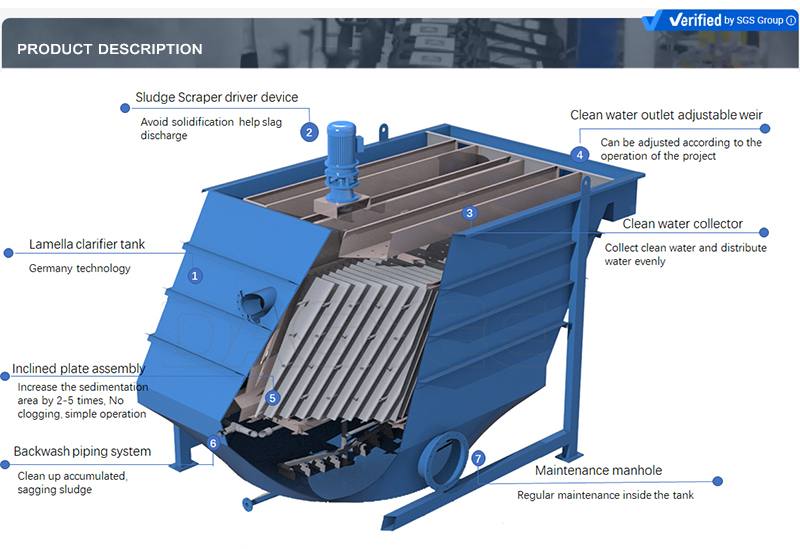

Lamella Separator Description

lamella clarifier inclined plate settler (IPS) a type of settler designed to remove particulates from liquids.They often employed in primary water treatment in place of conventional settling tanks. used in industrial water treatment. Inclined plates provide a large effective settling area for a small footprint. The inlet stream is stilled upon entry into the clarifier. Solid particles begin to settle on the plates and begin to accumulate in collection hoppers at the bottom of the clarifier unit. Sludge drawn off at the bottom of the hoppers and the clarified liquid exits the unit at the top over weir.

Available Options

Flash mixing/flocculation tank with agitator

Full glass steel or stainless steel structure

Concrete tank design

Special coatings and plates

Integrated mechanical sludge thickener

Overhaul platforms and ladders

In-house laboratory analysis to optimize equipment

Drinking water design

Gasket and removable cover

Automatic desilting

Instrumentation and control

Chemical feed equipment

Sludge treatment and dewatering

Pilot size units for field testing

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

|

DLC |

Capacities |

Piping Connections() |

Physical Dimensions(m) |

|||||

|

Inlet(a) |

Effluent(b) |

Sludge(c) |

Backwash(d) |

L |

W |

H |

||

|

DLC- |

5 |

80 |

80 |

50 |

50 |

2.55 |

1.6 |

2.9 |

|

DLC- |

10 |

100 |

100 |

50 |

50 |

3.35 |

1.82 |

3 |

|

DLC- |

15 |

100 |

100 |

50 |

50 |

3.35 |

2.02 |

3 |

|

DLC- |

20 |

100 |

100 |

50 |

50 |

3.35 |

2.02 |

3 |

|

DLC- |

30 |

150 |

150 |

50 |

50 |

4.2 |

2.22 |

3 |

|

DLC- |

40 |

150 |

150 |

50 |

50 |

4 |

2.8 |

3 |

|

DLC- |

50 |

200 |

200 |

50 |

50 |

4.65 |

2.82 |

3 |

|

DLC- |

60 |

200 |

200 |

50 |

50 |

4.7 |

3 |

3 |

|

DLC- |

70 |

250 |

200 |

50 |

50 |

6.4 |

2.6 |

3 |

|

DLC- |

80 |

250 |

200 |

50 |

50 |

6.8 |

2.82 |

3 |

|

DLC- |

100 |

250 |

250 |

50 |

50 |

7.05 |

3.02 |

3 |

Lamella Separator Advantages

Lamella Clarifier minimizes maintenance and operation;

The cost of compact design is much less than standard clarifying agent;

Lamella is great for new factories or upgrade existing installations with limited space system;

The configuration ensures laminar flow conditions, resulting in high hydraulic uniformity and high effluent quality point source;

Treatment with Lamella is very suitable for many applications.

Lamella Separator Applications

Gravel and sand industry

Recycling industry

Glass / Ceramics / natural stone

Chemical industry

Energy industry / cooling water

Tunneling / construction sites

Waste / Landfill / street-cleaning

Heavy metal precipitation

Municipal water treatment Systems

Wet scrubber and slaking effluents in the power industry

Thickening processes in the chemical, mining and mineral industries