Description

Lamella Separator Description

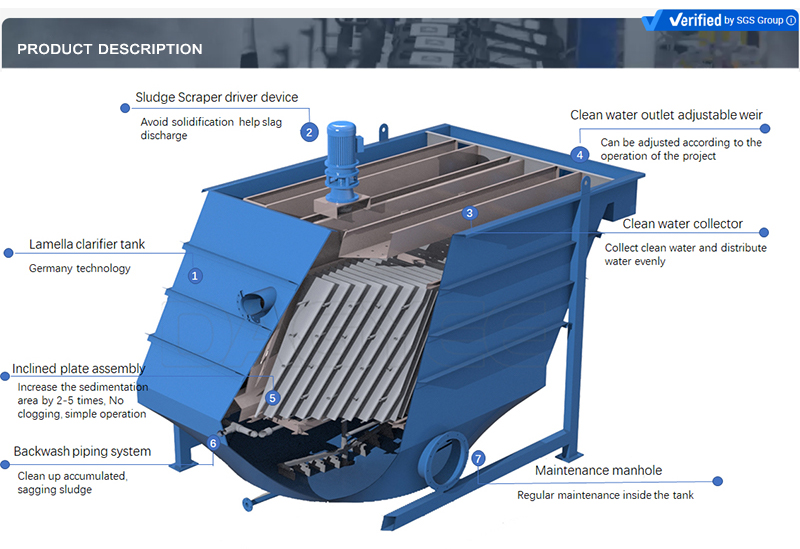

lamella clarifier also called inclined plate sediment tank. It is good at high efficient combined type settling tank; set many dense inclined tube packing in sediment area, to make the suspended impurity in water sediment, water rise flow along inclined tube, the separated sludge down to the tank bottom along the inclined tube by gravity, then discharge it in concentration. Such tank can improve sediment efficiency 60~70%, it can improve treatment capacity 3~5 times in the same area. It can design different flow rate inclined plate sediment device according to raw waste water test report, it need dose flocculant usually.

The clarifier consists of a series of inclined plates, which are arranged to form a separate sedimentation chamber between adjacent plates.

The raw water is first fed to Static Mixer. Chemicals like alum, poly electrolyte are added prior to static Mixer for proper mixing of chemicals in water.

Water from Static mixer enters in Flocculator in which paddle type agitator is provided for gentle mixing. Polymer is added for flocculation of coagulated particles.

Available options

Flash mixing/flocculation tank with agitator

Full glass steel or stainless steel structure

Concrete tank design

Special coatings and plates

Integrated mechanical sludge thickener

Overhaul platforms and ladders

In-house laboratory analysis to optimize equipment

Drinking water design

Gasket and removable cover

Automatic desilting

Instrumentation and control

Chemical feed equipment

Sludge treatment and dewatering

Pilot size units for field testing

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model |

Capacities (m3/h) |

Piping Connections() | Physical Dimensions(m) | |||||

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC- | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC- | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC- | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC- | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC- | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC- | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC- | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC- | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC- | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC- | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC- | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

Lamella Separator Advantages

Unit is Completely Assembled

Low Installation

Conservative Design 0.2 GPM/Ft2

Completely Automatic, Gravity in Gravity Out

Reduced Floor Space

Large Compartment Flocculation Tanks with Mixer for Extra Retention Time (approximately 50-60 minutes)

Lamella Separator Applications

Primary clarification of wastewater streams

Backwash water recovery

Industrial water treatment systems

Potable water treatment systems

River water abstraction clarification

Wash water recovery and recirculation systems

Wet scrubber and slaking effluent treatment