MBR Membrane BioReactor troubleshooting

MBR Membrane BioReactor troubleshooting

1. Blower

If the linkage between the fan and the water pump fails, the fan is heated severely or cannot be turned on, turn off the power in time and notify the maintenance department.If the fan stops running for more than 1 day (especially in summer), it can cause a large number of microbial deaths. If the system stops running for 1-3 days and then restarts, the activated sludge activity should be restored after the fan has been running for 1 day, and then the system should be in an automatic control state, and the water pump should run automatically. If the system stops running for a long time (more than 3 days) and then restarts, you must refer to the process of microbial domestication and culture in the MBR mode in the manual.

2. Air volume

If it is observed that the degree of agitation of sewage in the MBR reactor is significantly weakened, first check whether the air supply pipeline is normal, such as pipeline leakage, pipeline blockage, and fan filter system blockage.3. Water volume

If you observe a significant reduction in the amount of water produced by the MBR reaction, you should first check whether the vacuum of the vacuum gauge is normal. When the pressure difference between the membranes is 20KPa higher than the initial stage, chemical cleaning should be carried out when it is determined that the membrane surface is blocked by other reasons.If the MBR reactor does not produce water, first check whether the water level of the reactor is below the water level of the float. Secondly, check whether the float and the water pump fail. If they fail, notify the relevant maintenance department for replacement.

4. Water quality

If it is observed that the effluent quality of the MBR reactor is significantly deteriorated, first check whether the treatment membrane module and piping system are normal, and whether the color, state, smell and concentration of the activated sludge are normal. If the pretreatment device is not working properly, it should be eliminated in time. If the concentration of activated sludge is too low or the state is abnormal, the water pump should be turned off and only the fan should be turned on for bacteria culture. After the sludge concentration in the reactor is 6000-8000mg/L, when the activated sludge activity is restored, the water pump is turned on and the system is under automatic control.5. Vacuum

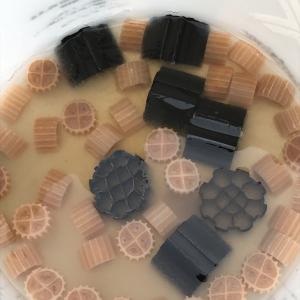

Regularly observe the vacuum degree of the vacuum gauge. When the vacuum degree of the vacuum gauge is greater than 0.04Mpa, it should be repaired immediately.6. Soak

Sewage contains more detergent, and sludge can produce more foam during aeration. If the foam is thick, fatty and creamy in appearance, it is produced when certain types of detergents are biodegraded. These detergents contain soluble grease, which cannot be removed in the pretreatment species, and enter the biological treatment system to form bubbles and concentrate and float. This is unavoidable in the aeration system. It is often related to the residence time of the sewage in the reactor It is too long (such as insufficient load, low flow at night).When the effluent quality is seriously affected, the following measures can be taken:

Add defoamer (only use it if the defoamer will not damage the film);

Spray water to remove;

Increasing the reactor sludge concentration is the simplest and most effective remedy.

If foaming occurs repeatedly, part of the detergent should be removed with raw water to solve the foaming problem. When the detergent content exceeds 40mg/L, it is harmful to biological treatment.

7. Sludge color and smell

The activated sludge of good quality is dark brown. The black sludge in the reactor usually means the beginning of corruption. The black sludge often emits the smell of hydrogen sulfide. This is due to the relative lack of aeration. The water outlet should be suspended or the aeration rate should be increased.