Description

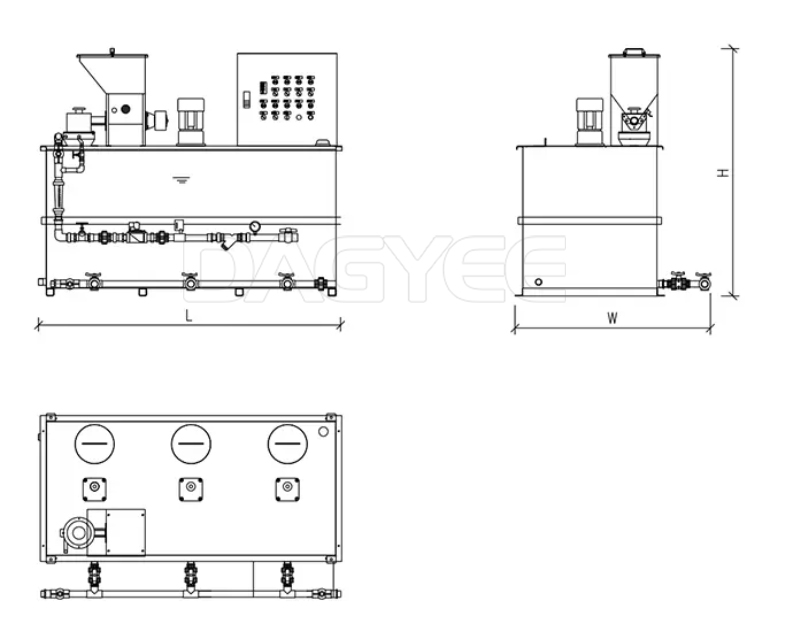

PAM polymer preparation unit Description

Integrated dosing device for automatic batching,dissolution and integration into one ,and Fully automatic operation.

The quantitative dosing device is accurate in measurement and driven by continuously variable transmission,it is convenient to adjust the feeding amount.The concentration range of preparation agent is large.

With liquid level detection, flow control, auxiliary vibration feeding and other functions, high degree of automation.4.Tank material: stainless steel SS304 or SS316L, polypropylene PP, FRP, etc.

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Feature

Safe and automatic control

PAM dosing: Inverted bag apparatus or Manual dosing

Accurate and adjustable chemical dosage, avoiding unnecessary waste

Easy maintenance, Attractive appearance, Small footprint, Compact structure

Strong technical support, design process according to user requirements

PAM Polymer Preparation Application

Municipal Sewage

Slaughter House

Metallurgical Industry Wastewater

Spraying Sewage

Printing & Dyeing Sewage

Metal-Processing Sewage

Mining Stone Wastewater

Electronic Sewage