Description

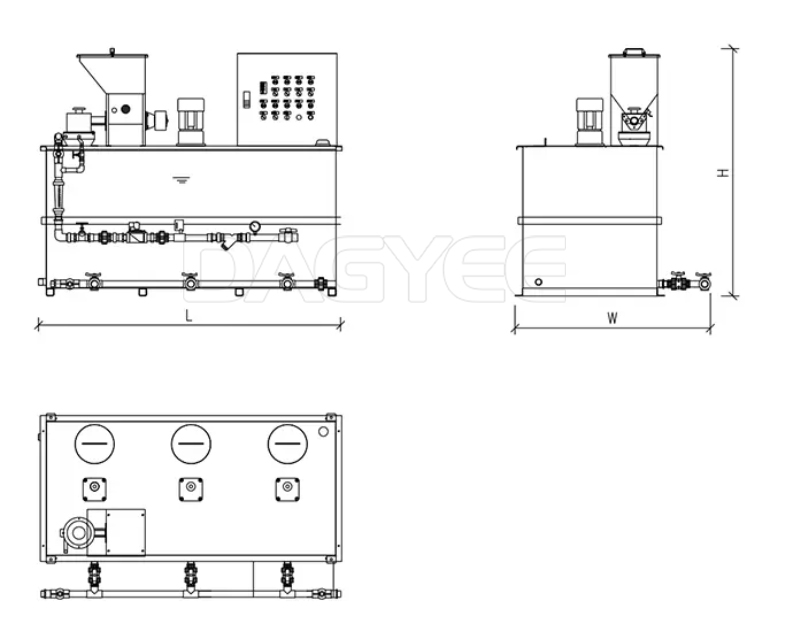

PAM polymer preparation unit Description

This device is an automatic and continuous powder dispensing and dosing system.The dry powder enters the premix and water from the screw at the bottom of the hopper for premix, and the wet material enters the mixing tank for dilution and mixing, and is prepared according to the concentration required by the user.

The preparation solution goes from the preparation tank to the curing tank and then into the storage tank. When the liquid level of the storage tank is at a high level, the preparation process will automatically stop, and when the solution drops to a low level, the batching process will automatically start.Agitator is set in both preparation tank and curing tank to ensure the dilution and curing of reagents.The prepared flow rate and concentration can be determined by adjusting the inlet flow rate and the rotating speed of the screw shaft.

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Feature

Automatically Operate

Amount of the powder feeding is exactitude

SUS304 crust, all imported parts

All message is output by touch

Guarantee the treatment effect, avoid waste

Attractive appearance

PAM Polymer Preparation Application

Optional equipment

Automatic powder hopper loading.

Minimum level probe in the powder hopper.

Stirrer in the batching tank.

Vibrator for hopper.

Prefabricated post-dilution systems.