Description

Wastewater Recycling System Dissolved air flotation

Dagyee DAF System proactively promotes solid/liquid separation providing better contaminant removal, more efficient chem usage and drier sludge – using a much smaller footprint than conventional DAFs. The DAF System is often referred to as a 'DAF on Steroids'. However, as opposed to DAF's that require significant retention time and rely on the old-school particle collision process to float solids, the DAF System injects air into 100% of the waste stream while pushing water through a series of hydrocyclones under controlled pressure, removing up to 100% of TSS & FOG. Chemicals are uncoiled in the Heads availing more than 2x the charge sites resulting in a higher rate of contaminant removal. Since separation occurs in the Heads, large tight flocs float and are skimmed off the tank into a sludge hopper. Drier sludge ensues as the air dissipates and chemicals recoil, to naturally dewater the flocs. Costs are reduced due to lower chemical, sludge handling and building costs.

| 40m3/hr Dissolved air flotation Specification | ||

| Parameter | Units | DAF 040 |

| DAF Flow Rate | m3/hr | 40 |

| Total Inlet Solids | mg/L | 500-6500 |

| FOG Removal | % | 80~97 (Application Dependent) |

| TSS Removal | % | 60~99 (Application Dependent) |

| COD Removal | % | 20~80 (Application Dependent) |

| BOD Removal | % | 20~80 (Application Dependent) |

| Power Consumption | kW | 4.7 |

| Footprint | m | 8*3.6 |

| Inlet | in | 6 |

| outlet | in | 6 |

| Sludge outlet | in | 6 |

| Vent | in | 4 |

|

STANDARD INCLUSIONS + OPTIONS ✓= Standard Supply, o = Optional Supply |

||

| Skimmer Mounted Plant | ✓ | |

| Feed Pump | ✓ | |

| Micro bubble generator | ✓ | |

| Recycle clean water system | ✓ | |

| Maintenance platform, ladder | ✓ | |

| Pre-Treatment | o | |

| Control System | ✓ | |

| Control System with PLC | o | |

| Air Compressor | ✓ | |

| Treated Water Recycling for Saturator | o | |

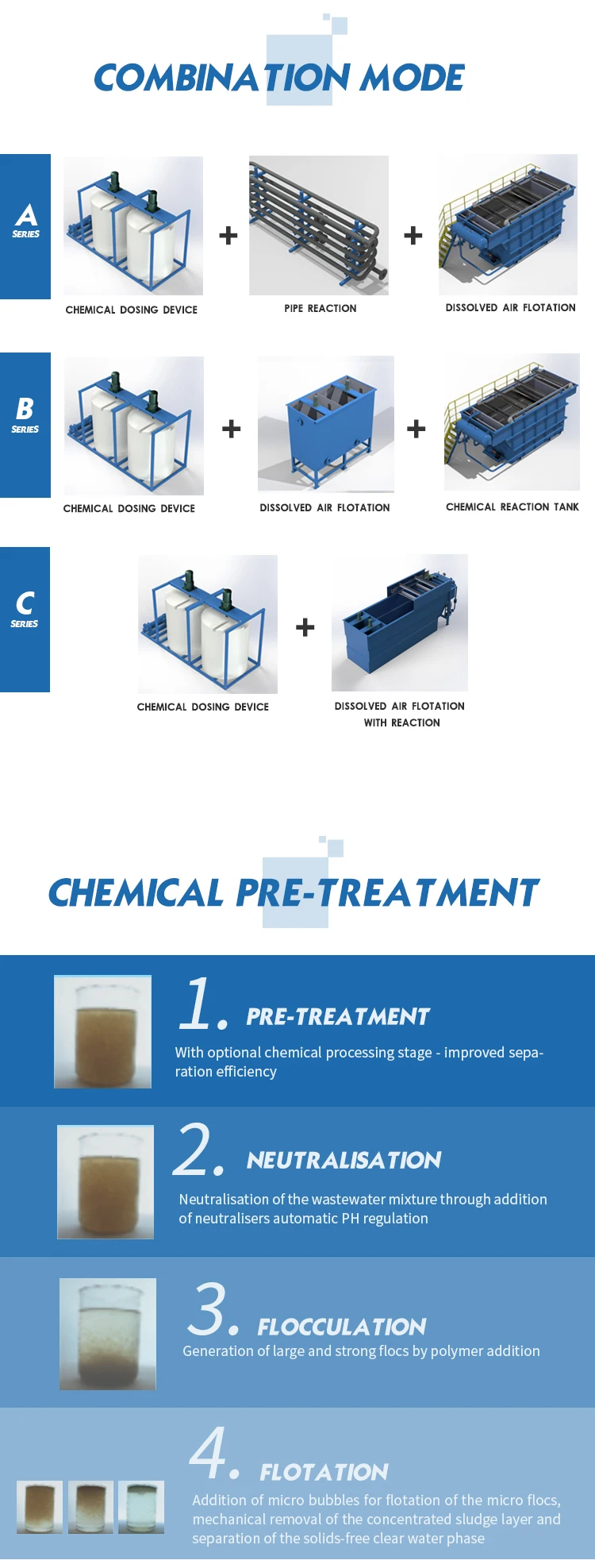

| Coagulation, flocculation reaction device | o | |

| Chemical powder dissolving dosing device | o | |

Characteristics of DAF Dissolved air flotation

- Flow rate of one set: 1-200 m³/h.

- Recycling flow dissolved air flotation.

- High efficiency pressurization system providing high quantity dissolved-air water to create micro bubbles.

- Custom design on different dissolved air flotation equipment and recycle flow ratio according to the type of wastewater treatment requirement to achieve target removal effect and stability.

- Adjustable PP chain type skimmer to suit the different quantity of sludge.

- Integrated coagulation flocculation tank and cleaning water tank(as optional)is available to save the space and cost.

- Automatic and remote controllable.

- Material of construction: carbon steel epoxy painted, carbon steel FRP line, SS304/SS316L.

Application of air flotation

- Solids separation upstream of secondary processes such as:

- Oxidation Ditches

- Sequencing Batch Reactors

- Biological Aerated Filters

- Dissolved Air Flotation -Moving Bed Bio Reactors -Membrane Bio Reactors Primary treatment for new plants Grit removal after a coarse screen

- Increase primary or secondary process capacity

- Plant expansion where land is expensive or unavailable

- Dig-free, concrete-free solution for mountainous or earthquake-prone areas

- Combined sewer overflow (CSO) treatment

- Stormwater treatment

Standard Features

- Adjustable effluent weir troughs

- Epoxy coated carbon steel tank

- Factory tested

- Seamlessly integrates with other Hydro-Flo offered wastewater products

- Stand alone operation

- Standard units can be manufactured for flows from 5 gpm to 3500 gpm and above, in a single above grade tank

- Structural steel support legs