Description

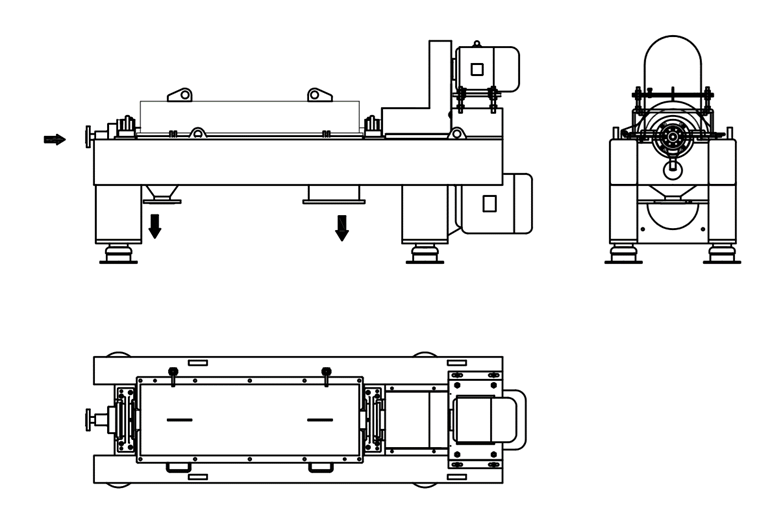

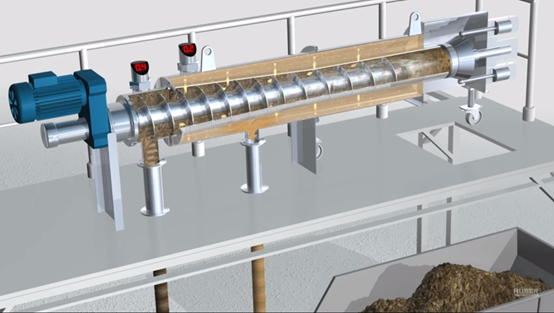

2 Phase Decanter Centrifuges Description

The machine starts and speeds up automatically.When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force,the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum.the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.The separated liquid flows out though the big end or will be driven out by centrifugal pump.

2 Phase Decanter Centrifuges Model

| Model |

Drum diameter

mm

|

Length

mm

|

Maximum speed

rpm

|

Hightest separation

factor g

|

Mixture capacity

m3/h

|

Motor Power

Kw

|

| LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 | 11/5.5 |

| LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 | 18.5/5.5 |

| LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 | 22/7.5 |

| LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 | 22/7.5 |

| LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 | 22/7.5 |

| LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 | 30/7.5 |

| LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 | 30/7.5 |

| LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 | 45/15 |

| LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 | 55/18.5 |

| LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 | 55/90 |

| LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 | 75/90 |

| LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 | 90/132 |

| LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 | 90/132 |

| LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 | 132/200 |

2 Phase Decanter Centrifuges Technical

All contact parts can be made by SS304/SS316L/Duplex Steel 2205 Automatic adjustment of differential speed via VFD,Siemens PLC Spiral :

Surfacing welding tungsten carbide grinding

Two motor drive

Approximately 80 to 90% of the oil is recovered

Low labor costs due to continuous and automatic operation

Highest g-force for higher solids output

Belts for both primary motor and secondary

NSK/SKF Bearing

2 Phase Decanter Centrifuges Features

The machine can operate with a higher throughput capacity than smaller machines.[5] This also reduces the number of units required

The device is simple to optimise and operate as it has few major variables and reliable feedback information.

The decanter centrifuge has reduced labour costs compared to other processes, as it requires low continuous maintenance and operator attention.

Compared to some competitive process such as the belt filter process, the decanter centrifuge has more process flexibility and higher levels of performance.

2 Phase Decanter Centrifuges Application

City tap water, domestic sludge dewatering;

Oil drilling mud dewatering;

Sludge Oil Recovery;

Refinery sludge concentrated dehydration;

Distiller's grains dehydration;

Paper, printing and dyeing wastewater separation;

Medical sludge dewatering;

Soy protein dehydration;

Plant oil clarification and separation;

Cosmetic clarification and separation;

Bleaching powder separation.