Description

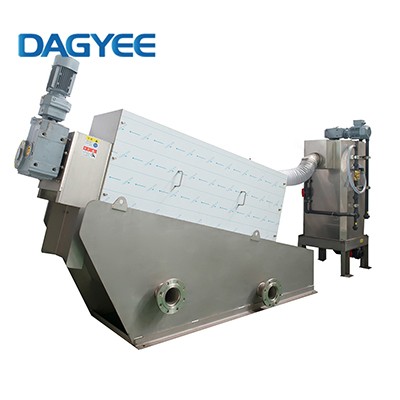

Screw Press Dehydrator

The DAGYEE SCREW PRESS provides a unique, cost effective solution for dewatering of municipal and industrial sludge.

The equipment is designed to dewater the Primary Sludge and Secondary Sludge dewater sludge from a dry content of 0.8-4% to 15-20%.

The sludge is fed to the machine via pump or inlet hopper into a cylindrical 250 microns wedgewire drum.

A VFD controlled variable speed shafted auger transports the solids towards the drum discharge.

The auger shaft is tapered with a smaller diameter on the inlet side and a larger diameter on the discharge side.

Consequently, the space between the shaft and drum reduces as the solids reach the discharge side. The counter pressure of the cone maximizes the DRYCAKE effect.

Typically polymer addition is required for flocculation of the sludge and for best capture rate and dry cake.

The cleaning system of the drum is provided by a motorized water washing system under pressure with brushes installed on the external surface of the screw conveyor.

The cleaning system of the drum is provided by brushes installed on the external surface of the screw conveyor and a motorized washing system covering 70% of the drum surface without need.

Screw Press Dehydrator Features

- Maximize Capacity: Solids Loading, Flow Rate

- Maximize Cake Solids

- Minimize Polymer Usage

- Stable performance: consistent cake solids

- Reduce Operating Labor

- Lower Energy Costs

- Reduce maintenance costs

- Increase Screw Press availability

- Improve material handling properties

Screw Press Dehydrator Technical Table

| Model | DL301 |

| DS capacity kg/h | 30--50 kg/h |

| Sludge capacity m3/h(2-50g/L) | 1-15 |

| Spiral diameter mm | ¢310*1 |

| Discharge Distance mm | 495 |

| Size L*W*H mm | 3255*985*1600 |

| Net.Kg | 850 |

| Run Kg | 1320 |

| Power Kw | 0.74 |

| Washing Q L/h | 40 |

Screw Press Dehydrator Application

- All range of industries ETP & STP

- Faecal Sludge management

- Primary sludge and biological sludge dewatering

- Wastewater treatment plants – New / Existing