Description

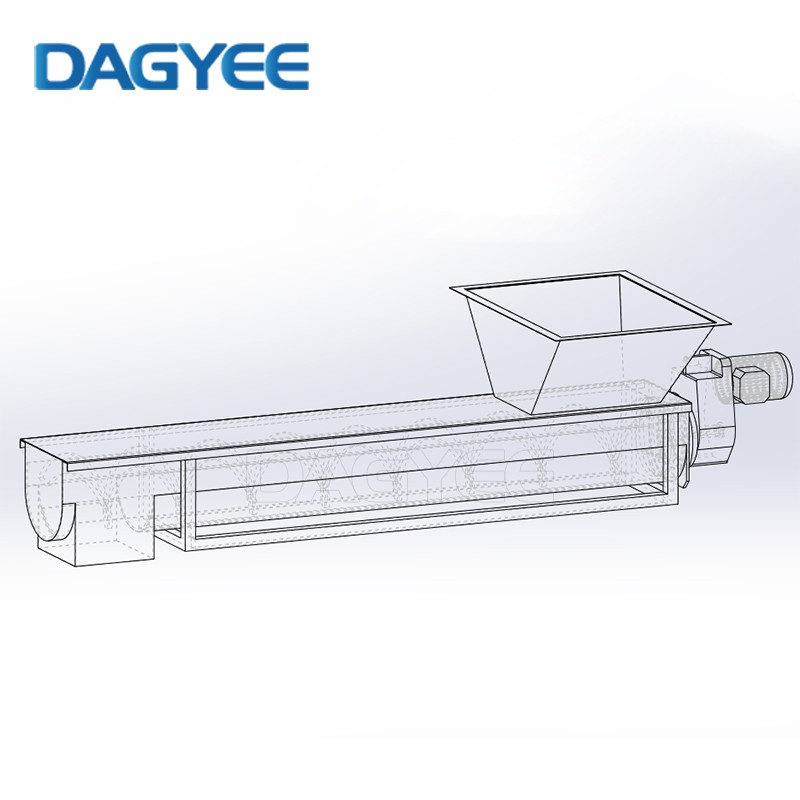

Product Description:

Shaftless Screw Conveyor according to the building material, chemical industry, environmental protection,electric power, medicine, metallurgy, food and other industries in the LS type, GX type screw conveyor conveying grinding cut big, viscosity is bigger, is easy to agglomerate, wrapping easily material formed when material blockage, suspension bearing damage to the actual situation of screw machine doesn't work and independent research and development of a new type of screw conveyor. This product is suitable for continuous and uniform conveying of loose, sticky and easily wound materials, the temperature of conveying materials is up to 100℃, the maximum inclination Angle is less than 30°.

Model & Installation Dimensions:

This product is mainly composed of drive device, head assembly, housing, no shaft helix, slot liner, feed port, discharge port, cover (when needed), base, etc.

- Driving device: cycloidal needle wheel reducer or shaft mounted gear reducer with hard tooth surface shall be adopted. The driving device shall be set at the outlet of the material as far as possible in the design to make the helix in the state of tension during operation.

- The head is equipped with thrust bearing, which can bear the axial force generated during material transportation.

- Housing: the housing is u-shaped or o-shaped, with a rain-proof cover on the top. The material is stainless steel or carbon steel or fiberglass.

- No shaft helix: the material is stainless steel or carbon steel.

- Slot lining board: wear-resistant plastic board or rubber board or cast slate, etc.

- Inlet and outlet: there are two types of inlet and outlet: square and round. The general inlet and outlet form is determined by the user.

Main features:

- Shaft-less structure, less contact with the residue, low friction, the extrusion efficiency can be improved. No clogging and no winding.

- Made of stainless steel with high strength, good corrosion resistance and long service life.

- Driving device adopts axle direct drive mode, which is stable, reliable, and energy saving.

- Outlet is assembled with a spring baffle to increase the extrusion pressure and increase the dehydration rate.

- Except for the inlet and outlet, the rest structure is closed, and the environment is clean and sanitary.

Product Application:

- Ceramic industry: clay, silica, sand, polishing materials, etc.

- Food industry: soybean, peanut, starch, milk powder, salt, sugar, etc.

- Plastics industry: plastic powder, plastic particles, etc.

- Wood industry:wood chips, wood sawing surface and byproducts, etc.

- Environmental: the filter material, fly ash, fixed residue, waste, etc.

- Agriculture:livestock feed, food, powder, etc.

Product Details:

|

Certification |

SGS/CE/ISO 9001 |

|

Horizontal rotation speed |

18rpm |

|

Incline rotation speed |

>18rpm |

|

Material |

SS304/316 |

|

Screw diameter |

380mm |

|

Conveying length |

customize |

|

Motor power |

1.1-3KW |

|

Operation |

Full automatic |

|

Protection level |

IP55 F |

|

Warranty |

1 year |

|

Product keywords |

slurry screw conveyor,sludge transportion,sludge cake conveyor |