Description

WHAT IS SIEVE BEND SCREENING

Cost-effective, reliable fine screening technology

DAGYEE provides proven and reliable performance in liquid-solid separation in municipal and industrial applications, especially for screening fibrous and non-oily solids. There are no moving parts, motors or complicated connections. Static screens are economical and easy to operate.

The opening size ranges from 0.25 to 2.5 mm, and the hydraulic capacity ranges from 4 to 200 cubic meters per hour or more, depending on the type of water and solid content. The standard structure uses 304 stainless steel. Heavy-duty models can be used for heavy solid loads.

DAGYEE provides reliable performance in liquid-solid separations for municipal and industrial applications, especially when sieving fibrous and non-oily solids. There are no moving parts, motors or complicated connections. Liquid solid separation screens are economical and simple to operate.

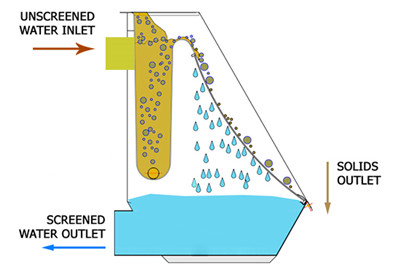

HOW DOES STATIC SCREEN WORKS

WHY CHOSE STATIC SCREEN

Advantages from simple design and robust construction

- No moving parts, no motor

-

Very low installation cost, no maintenance required

-

Only need regular cleaning

-

Quiet operation

-

V shape of the bar provides a self-cleaning effect on the screen

Static hydraulic screen

- A Better Environment for Beaver Pond

- Whitewater Reuse

- Broke Thickening

- Helps Nut Grower Recycle Wastewater

- Screening fire sprinkler water

- Storm water screening

- Better Dairy Pen Waste Management

- Textiles and laundries

- Fruit and vegetable canning

- Wine producers and distilleries

- Meat and processed meals industry

- Slaughterhouse

- Fish processing

- Breweries and dairies

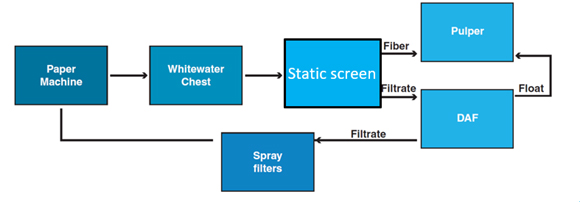

STATIC SCREEN USED WITH DAF UNITS

Used for Dissolved air flotation as a core product, static screen as a pretreatment before Dissolved air flotation . These screens facilitate a consistent flow and reduce the amount

of suspended solids going to the DAF unit.

In wastewater treatment plants, our static screening equipment is famous for fine screens used for pretreatment and as gravel dewatering equipment. Industrial users such as meat processors, food processors, tanneries, textile mills and recyclers all rely on it for product recycling and wastewater treatment. Pulp and paper mills use it for fiber recycling and refuse to dispose of it.