Description

Shaftless Screw Conveyor Description

Shaftless screw conveyor according to the building material, chemical industry, environmental protection, electric power, medicine, metallurgy, food and other industries in the LS type, GX type screw conveyor conveying grinding cut big, viscosity is bigger, is easy to agglomerate, wrapping easily material formed when material blockage, suspension bearing damage to the actual situation of screw machine doesn't work and independent research and development of a new type of screw conveyor. This product is suitable for continuous and uniform conveying of loose, sticky and easily wound materials, the temperature of conveying materials is up to 100℃, the maximum inclination Angle is less than 30°.

Shaftless Screw Conveyor Structure

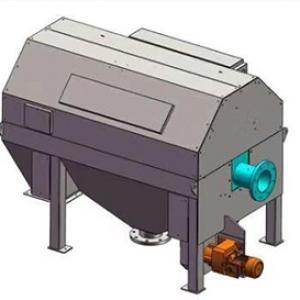

Shaftless screw conveyor is mainly composed of shaftless screw, U-shaped spiral groove, cover plate, lining plate, inlet and outlet, discharge outlet and driving device.

Shaftless Screw Conveyor Type

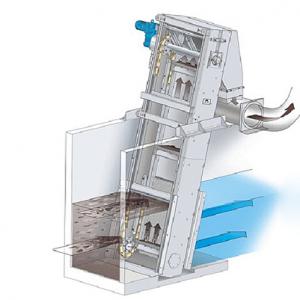

Single shaftless screw conveyor screw shaft, without mixing and stirring functions.

Twin Shaftless Screw Conveyor It adopts double screw blades with mixing and stirring functions. The two screw blades rotate in opposite directions to avoid material blocking. The conveying capacity is 1.5-2 times that of a single shaft.

Inclined Shaftless Screw Conveyor mainly used for conveying materials at a small angle of 25°.

Shaftless Screw Conveyor Technical

|

DLS

Model

|

Capacities

(m3/h)

|

Length | Speed | Size | ||||

| 00 | 150 | 300 | (m) | (r/min) | A(mm) | B(mm) | B0(mm) | |

| DLS200 | 2 | 1.4 | 0.9 | 10 | 20 | 200 | 310 | 270 |

| DLS260 | 3.5 | 2.5 | 1.5 | 10 | 20 | 260 | 370 | 340 |

| DLS320 | 9 | 6.5 | 4.1 | 15 | 20 | 320 | 430 | 400 |

| DLS355 | 11.5 | 7.8 | 5.5 | 20 | 20 | 355 | 465 | 435 |

| DLS420 | 15 | 11 | 7.5 | 20 | 20 | 420 | 530 | 500 |

| DLS500 | 30 | 25 | 21 | 20 | 20 | 500 | 560 | 680 |

Shaftless Screw Conveyor Benefits

Shaft-less structure, less contact with the residue, low friction, the extrusion efficiency can be improved. No clogging and no winding.

Made of stainless steel with high strength, good corrosion resistance and long service life.

Driving device adopts axle direct drive mode, which is stable, reliable, and energy saving.

Outlet is assembled with a spring baffle to increase the extrusion pressure and increase the dehydration rate.

Except for the inlet and outlet, the rest structure is closed, and the environment is clean and sanitary.

Shaftless screw conveyors VS Shafted Screw Conveyors

Conveying materials

Shaftless is suitable for conveying sludge, household garbage, grid slag and other viscous, entangled materials and massive materials. It is precisely because the design of the shaftless screw conveyor without a central axis has great advantages for these materials.

The shaft screw conveyor is suitable for conveying materials: powder, small particle materials, etc. If you convey viscous materials such as sludge, it will stick to the inner tube shaft and blades, and the conveying block materials are easy to jam.

Conveying form

Shaftless screw conveyor is suitable for: horizontal conveying, and the large inclination angle should not exceed 20°, according to the actual usage.

The shaft screw conveyor is suitable for: horizontal conveying, inclined conveying, and vertical conveying.

Conveying capacity

Due to the use of shaftless, the single-machine conveying length of the shaftless screw conveyor can reach 60 meters, and the conveying capacity is 1.5 times that of the traditional shafted screw conveyor with the same diameter.

Shaftless Screw Conveyors Application

Shaftless Screw (Spiral) Conveyors are specially designed for handling difficult, heterogeneous materials such as urban solid waste, screenings and floating matter, de-watered, thickened, conditioned sludge, packaged food, creams or pastes, as well as waste from: meat, fish, fruit and vegetable processing.

The main sectors of application are: wastewater treatment, sugarhouse rejects, fish industry, solid waste treatment, fruit and vegetable processing, beverage industry, pulp and paper, chemicals, food industry in general, meat processing plants, abattoirs/ slaughterhouses, restaurants, canteens, catering in general.