Description

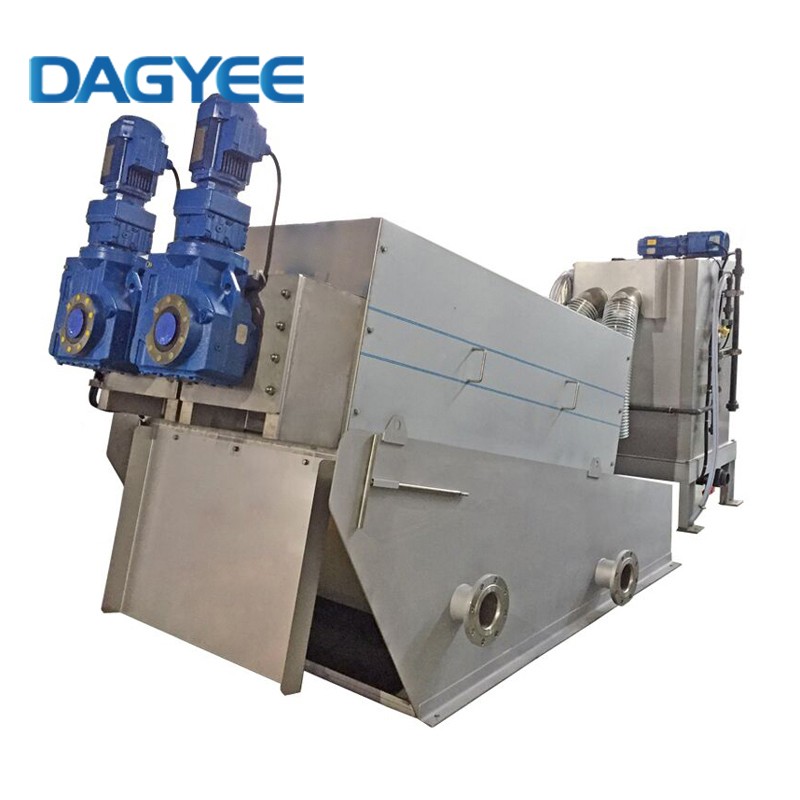

Screw Press Dehydrator

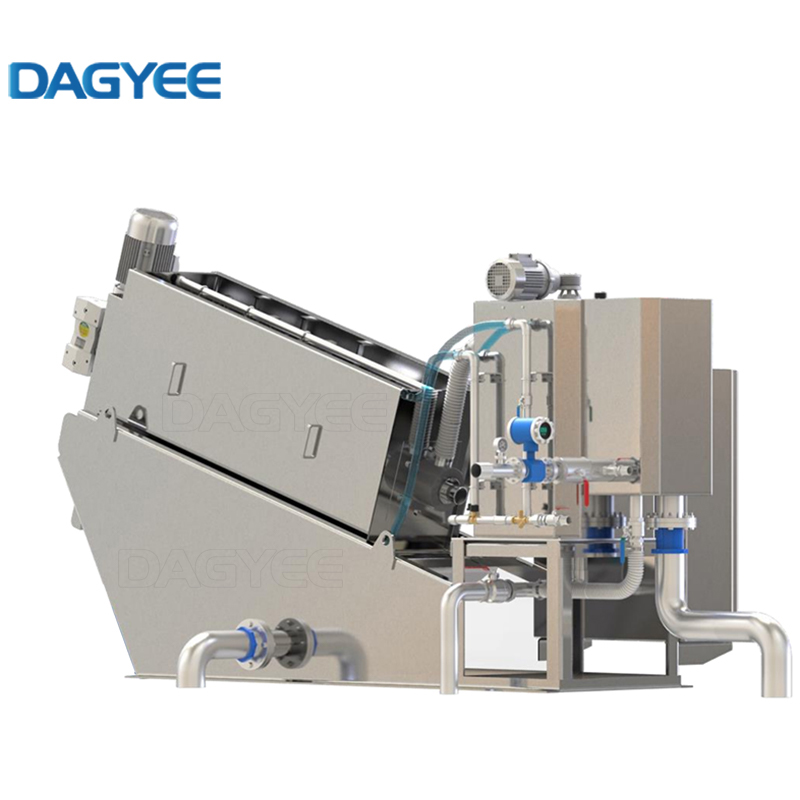

Multidisc are arranged one after other with alternate disc being moving and fixed.The gap between the plates acts as media for fine filtration.

The screw press main unit requires very very low power motor and the filtration surface area consists of a multiple discs which are self-cleaning, and generally do not clog, thus, the sludge press can be used continuously.

The main unit of the sludge dewatering screw press is of multi-shaft design.

Hence,when two or more main units are configured into one machine, any individual shaft can be repaired or serviced without interrupting operations.

Multidisc sludge dewatering screw press is integrated with sludge flocculation tank which efficiently mixes the input sludge with the optimal dose of flocculation. This flocculated sludge then enters the screw body which in the initial stage has more open area to dewater the separated water faster.

As screw rotates at a rpm which is set to give optimum output carries the dewatered concentrated sludge forward towards the end.

As screw is been gradually increasing making the valley / volume available for the sludge narrow towards the outlet so that flocculated sludge that is concentrated by gravity filtration is further dewatered by compression.

Screw Press Dehydrator Features

- No secondary pollution

- The screw shaft rotational speed about 2~3r/min, no vibration and noise is very small

- Only need a small amount of water for self-cleaning, no secondary water pollution

- Sludge runs at a slow operating condition. The smell does not spread

Screw Press Dehydrator Technical Table

| Model | DL132 |

| DS capacity kg/h | 12--20 kg/h |

| Sludge capacity m3/h(2-50g/L) | 0.4-6 |

| Spiral diameter mm | ¢130*2 |

| Discharge Distance mm | 250 |

| Size L*W*H mm | 2069*910*1040 |

| Net.Kg | 275 |

| Run Kg | 450 |

| Power Kw | 0.62 |

| Washing Q L/h | 48 |

Screw Press Dehydrator Application

- Simple arrangement

- Low Power Consumption

- Simple and short start-up and shut down procedures

- Continuous operation hence continuous output can be obtained

- Process can be automized

- Only electricity and water supply for cleaning is required, and that too in less amount

- For a multi-channel machine, one or more channels may be removed for maintenance purposes, while the machine with the remaining channels may still be operated

- No clogging. Cleaning is automized and is easy

- Long life of discs

- No external lubrication system is required

- Flocculator built in the Screw press