Description

WHAT IS INTERNAL DRUM SCREEN

DAGYEE Rotating screen drums are ideal for small wastewater flows. Capacity can handle flows between 20 and 400 m3 /hr,rotating drum screens are easy to install plug and play and only require a small investment. The screening space available is between 0.25 and 2.5 mm. screening space allows a much better final product sludge and effluent to be obtained from the wastewater treatment plant less non biodegradable waste, which is important in the event of an agricultural evaluation of the sludge and reject standards for effluent.

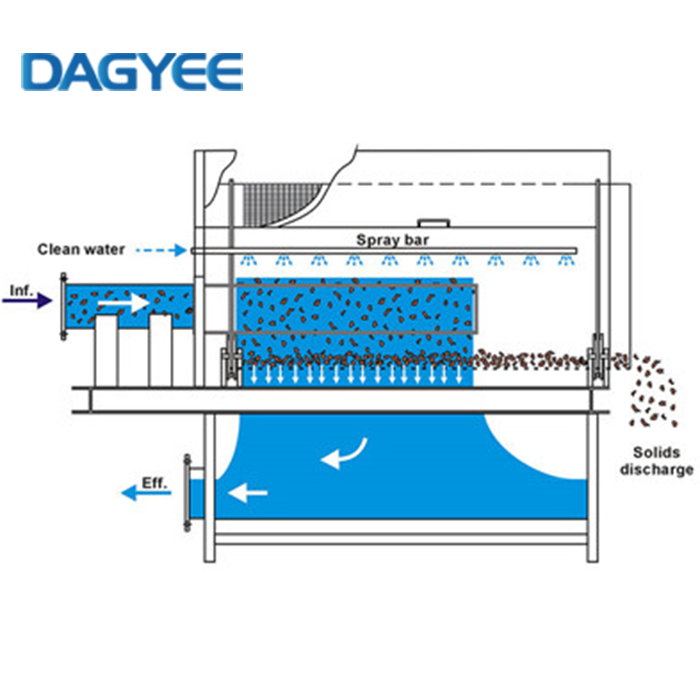

HOW DOES INTERNAL DRUM SCREEN WORK

The internal feed rotary screen operates very easy. Influent water enters through the inlet and flows into the headbox. The headbox is filled with water and the inlet overflows onto the weir and contacts the sides of the rotating cylinder screen. When the incoming water hits the rotating screen, the solids are trapped in the cylinder and the liquid enters the process through the screen or continues to be processed. A splitter on the cylinder moves the solid along the length of the screen for discharge. The device is equipped with spray bars head to clean the screen.

TECHNOLOGY INTERNAL DRUM SCREEN

- Internal water inlet, high removal rate ;

- Adjustable drum speed, low energy consumption ;

- Backwashing mode can be set to adopt the most water saving mode ;

- Structure of the equipment is made of stainless steel and corrosion resistant.

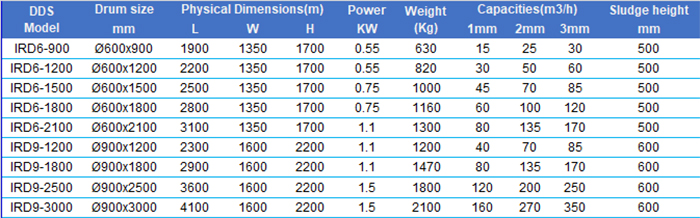

INTERNAL DRUM SCREEN TABLE