Description

Compact Units Pretreatment Plants For Wastewater Treatment Description

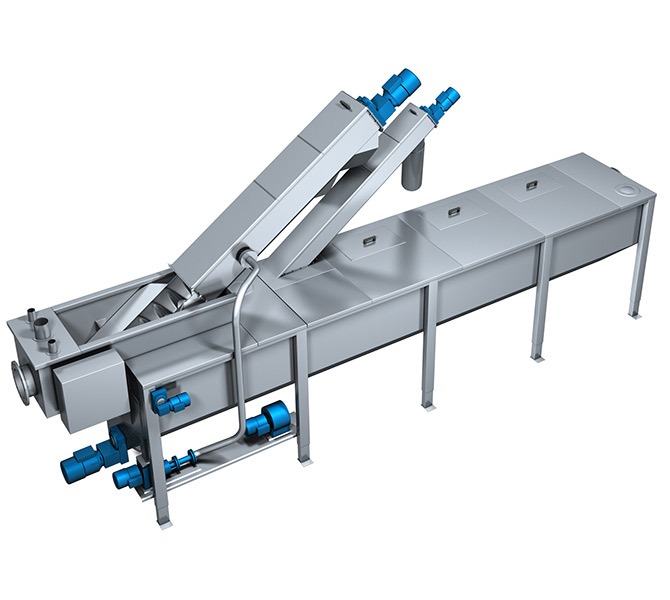

The Lackeby Pre-treatment unit is ideally suited for municipal and industrial waste water treatment plants requiring a compact, customised solution to their waste water separation requirements. Available in varying configurations and with the option of pre-screening installed on the unit such as the Lackeby Roto-sieve the unit achieves screening removal, washing and dewatering along with grit removal and grease separation.

Wastewater, which is pre-treated, is effectively cleaned of up to 90%of particles larger than 0.16mm at the design flow.

Installation and commissioning of this unit requires very little input as the unit is supplied essentially ready to operate and maintains a very small dimensional footprint.

Combined Screening Component

Dependable, complete and compact unit

performing the following process steps:

Fine screening

Screenings dewatering

Grit separation

Grit dewatering

Grease separation and removal (optional)

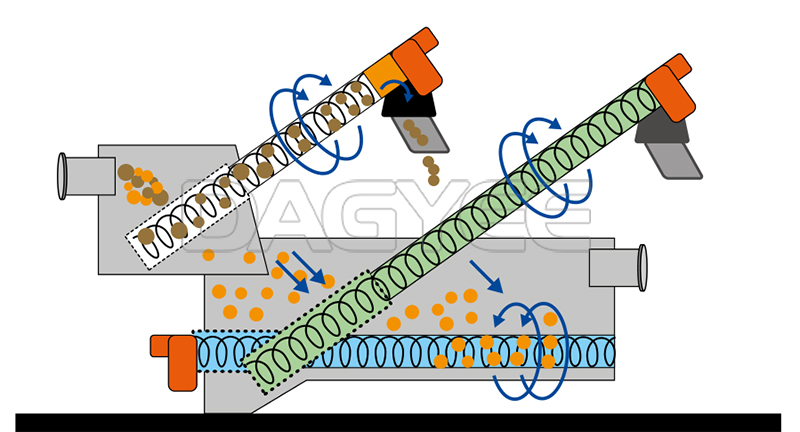

Combined Screening Working Principle

Combined unit for wastewater pretreatment Introduce sewage treatment plants. they perform Fine screening, grit removal and optional grease removal.Wastewater passes through spiral screen, solids Materials larger than the mesh size,The size is captured and removed from the system. they are compaction at the end of the screen conveyor before unloading.

The wastewater flows into the sedimentation tank. finer solid matter still present in wastewater Settled in a tank and conveyed to a hopper by a horizontal screw conveyor is placed at the bottom of the tank. OneInstallation of inclined screw conveyor for sand removal conveying the sand accumulated in the hopper,Drain into a container. filtered water leaves The system passes through an outlet tube placed on the upper level.Grease removal unit can be integrated into DAGYEE combination units are available upon request.

The wastewater firstly enters the tank where a screw screen is placed.

Big size solid materials are filtrated by the screw screen and a screw conveyor moves the solid materials captured up to the discharge point. At the end of the conveyor, they are pressed by the compaction unit before discharge.

The water which has still solid materials in smaller sizes flows through the sedimentation tank. The particles are settled by time and a horizontal screwconveyor transports them to the collection hopper.

Finally, they are conveyed by the grit removal screw conveyor to the discharge point.

Combined Screening Parameter

Power

Specifications

Model

Capacity

(m3/h)

Tank Length(mm)

Tank Width(mm)

Inlet Flange DN

Outlet Flange DN

Max.Wash Water(L/S)

DSP-30

30

4200

1200

DN200

DN200

0.5

DSP-50

50

5800

1200

DN200

DN200

0.5

DSP-100

100

7000

1200

DN250

DN250

1

DSP-150

150

7000

1200

DN250

DN250

1

DSP-200

200

8000

1500

DN300

DN300

1

DSP-250

250

8500

1500

DN350

DN350

1

DSP-350

350

10000

1500

DN400

DN400

1

DSP-400

400

12000

1800

DN500

DN500

1

DSP-500

500

15000

2000

DN500

DN500

1

Power Specifications

Model

Screw

Screen Power(kw)

Screw

Conveyor Power(kw)

DSP-30

0.55

0.25

0.37

0.18

DSP-50

0.55

0.35

0.37

0.18

DSP-100

0.75

0.37

0.55

0.18

DSP-150

0.75

0.37

0.55

0.18

DSP-200

0.75

0.55

0.75

0.18

DSP-250

1.1

0.55

0.75

0.18

DSP-350

1.1

0.55

0.75

0.18

DSP-400

1.1

0.55

0.75

0.18

DSP-500

1.1

0.55

1..1

0.18

Combined Screening Features

Filtration

Wash / compaction of solids removed

Extraction of sand

Degreasing (on GDF/D version)

Vantaggi

No odor

Low operating costs and maintenance

Reduced space requested

Construction work is not necessary

Ease of installation and management

Low organic matter in the solid residue extracted

Reduction up to 40% in volume of solids removed

Combined Screening Applications

Solids recovery

Filtration from 1 to 6 mm

Washing and dewatering

Recovery of sand and grease

Treatment capacity from 10 l/s to 240 l/s

100% of frame and components made out stainless steel

Combined Screening Functions

Screening

Washing/compacting of solid removed

Sand/grit separation

Degreasing

Main advantages

Odor-free

No clogging

Low maintenance and operation costs

Low room needed

No construction works needed

Easy to install and operate

Very low residual organic content in the washed out solid

Volume reduction (up to 40%) of the washed out solid