Detailed of DAF dissolved air flotation operating procedures

Detailed explanation of air flotation tank operating procedures

Dissolved air flotation tank function

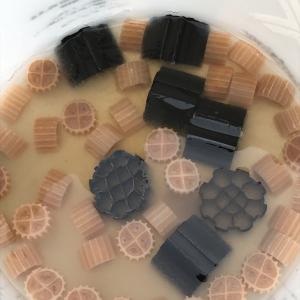

The air flotation tank is mainly used to pretreat the suspended solids, colloids and most of the organic matter in the sewage. The effect of forming alum in the reaction zone is good (large and dense), and the overall effect of agglomeration of scum in the floating zone is good. The scum is scraped off in time and the air floats The water must be relatively clear to reduce the subsequent processing load of the biochemical pond.

Dissolved air flotation tank function:

(1) Water volume control: the air flotation tank must maintain a certain water level before starting up (generally higher than the dissolved air pump inlet flow meter); adjust (in the adjustment tank) the opening of the pump outlet valve or the return pipe valve to make the inlet float tank react The water volume in the area is less than the processing capacity of the air flotation tank (the upper limit fluctuation range does not exceed 10%);

(2) The coagulation reaction effect requirements of the reagent in the reaction zone: first start the dosing system and then start the water intake. When shutting down, turn off the water pump and stop dosing; dosing PAC in the first cell of the reaction zone (if the pH is lower than 6.0 This grid also needs to add alkali to increase the pH value to 7-8, often test this pH value) to complete the coagulation reaction (neutralization); enter the second grid to add PAM (viscous organic agent) to complete flocculation The reaction, even if small particles of alum flowers condense into large particles of alum flowers, to improve the effect of trapping alum flowers by the scum layer in the air flotation zone, the reaction is to see obvious flocs (alum flowers), water and flocs have obvious stratification. Standard; PAC dosage and PAM dosage shall be adjusted in time according to the water quality and reaction situation on site;

Operation steps and requirements of dissolved air pump:

(1) Before starting up: confirm that the motor rotation is consistent with the direction indicated by the water pump. It is strictly forbidden to reverse the damage to the water pump. Before starting up, open the water volume regulating valve on the water inlet pipe and the valve on the water inlet floating pool pipe of the dissolved gas tank;

(2) Startup: Turn on the start button of the dissolved air pump, and when the motor reaches the rated speed, slowly open the outlet valve of the dissolved air tank (intake floating pool pipe), adjust the outlet pressure of the dissolved air pump to 0.5MPa; then slowly close the water inlet The regulating valve makes vacuum appear on the inlet side of the dissolved air pump. When the vacuum pressure gauge at the inlet of the dissolved air pump is 0.01-0.02MPa (negative pressure), open the air intake regulating valve to make the air intake reach the water flow rate of the dissolved air pump 10%-15%, at this time the dissolved air pump inlet water volume (return water volume) is 20-30% of the air flotation tank processing capacity, and the dissolved air pump outlet pressure drops to the normal range, that is, 0.4-0.5MPa (bubble diameter ≤ 30μm, air The solubility is better).

(3) Shutdown: Since the outlet of the dissolved air pump is equipped with a check valve, there is no need to close the outlet valve of the dissolved air tank; press the stop button of the dissolved air pump, and then close the water inlet valve. If the dissolved air pump is shut down for a long time, the water in the pump body should be drained to prevent the water pump from freezing and cracking and scaling after shutting down.

Operation steps of slag scraper:

(1) Check whether the slag scraper is in good electrical connection; whether the wheel-rail contact and engagement are good, whether the travel switch is sensitive, and enter the next step after it is normal;

(2) When the thickness of the scum is 3-5cm (the slag layer has been formed), turn on the slag scraper button to scrape the slag, and adjust the liquid level of the air flotation zone to discharge the air flotation sludge in time to ensure the effect of water discharge; The clear water from the air flotation zone enters the sludge bucket of the air flotation tank to reduce the sludge output; the slag scraping time (cycle) is generally 2-3 minutes, but it should be adjusted according to the specific slag volume;

(3) Shutdown: After the slag scraping is completed, the machine needs to be shut down. After the scum layer is formed again, it will enter the next slag scraping cycle; if the machine needs to be shut down (including accidents), press the slag scraper shutdown button.