Description

Efficientive Dissolved air flotation Thickener Wastewater Treatment

Dagyee DAF System proactively promotes solid/liquid separation providing better contaminant removal, more efficient chem usage and drier sludge – using a much smaller footprint than conventional DAFs. The DAF System is often referred to as a 'DAF on Steroids'. However, as opposed to DAF's that require significant retention time and rely on the old-school particle collision process to float solids, the DAF System injects air into 100% of the waste stream while pushing water through a series of hydrocyclones under controlled pressure, removing up to 100% of TSS & FOG. Chemicals are uncoiled in the Heads availing more than 2x the charge sites resulting in a higher rate of contaminant removal. Since separation occurs in the Heads, large tight flocs float and are skimmed off the tank into a sludge hopper. Drier sludge ensues as the air dissipates and chemicals recoil, to naturally dewater the flocs. Costs are reduced due to lower chemical, sludge handling and building costs.

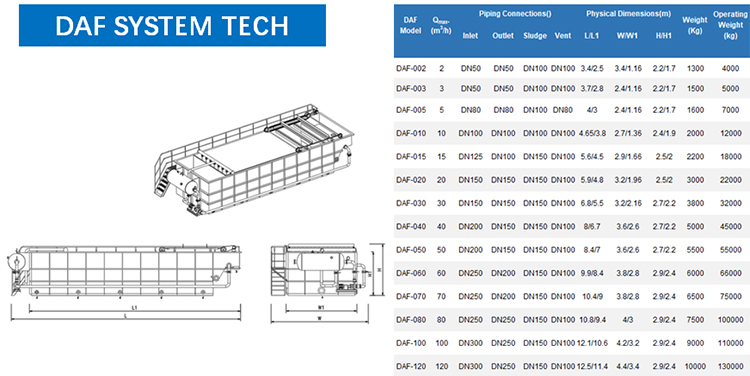

| 20m3/hr Dissolved air flotation Specification | ||

| Parameter | Units | DAF 020 |

| DAF Flow Rate | m3/hr | 20 |

| Total Inlet Solids | mg/L | 500-6500 |

| FOG Removal | % | 80~97 (Application Dependent) |

| TSS Removal | % | 60~99 (Application Dependent) |

| COD Removal | % | 20~80 (Application Dependent) |

| BOD Removal | % | 20~80 (Application Dependent) |

| Power Consumption | kW | 3.15 |

| Footprint | m | 5.9*3.2 |

| Inlet | in | 6 |

| outlet | in | 6 |

| Sludge outlet | in | 6 |

| Vent | in | 4 |

|

STANDARD INCLUSIONS + OPTIONS ✓= Standard Supply, o = Optional Supply |

||

| Skimmer Mounted Plant | ✓ | |

| Feed Pump | ✓ | |

| Micro bubble generator | ✓ | |

| Recycle clean water system | ✓ | |

| Maintenance platform, ladder | ✓ | |

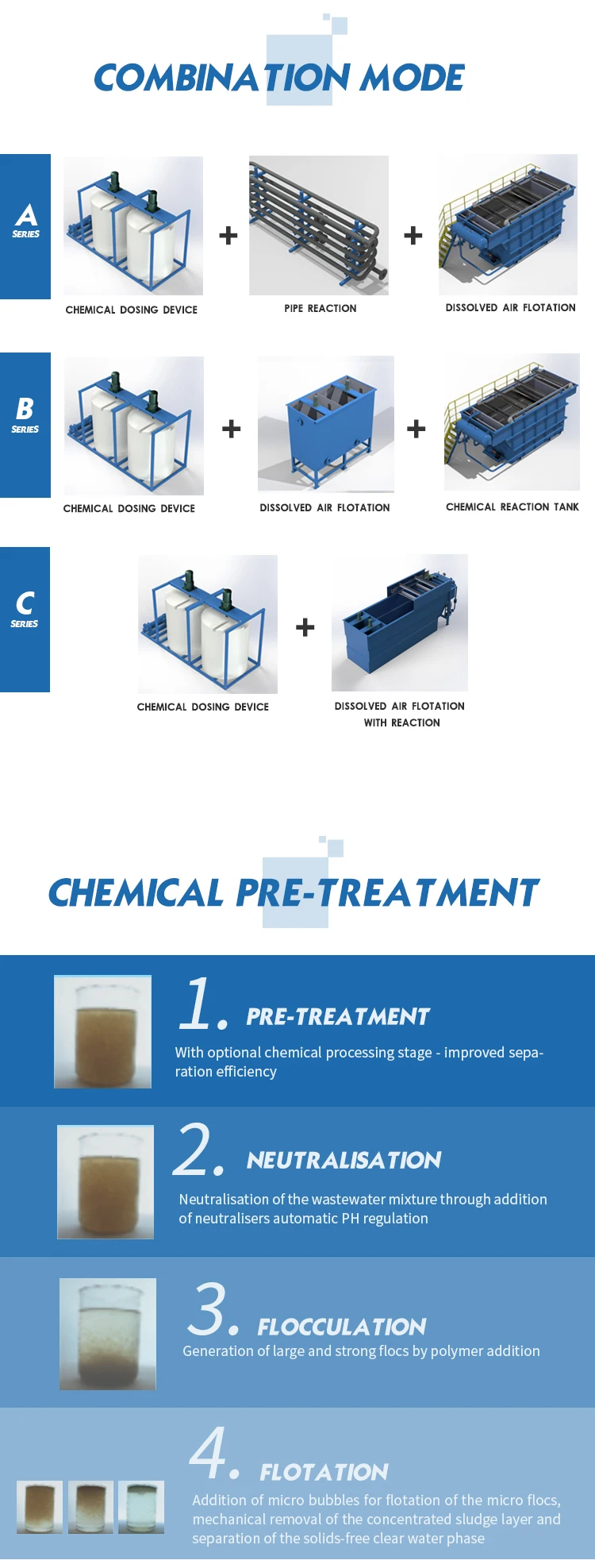

| Pre-Treatment | o | |

| Control System | ✓ | |

| Control System with PLC | o | |

| Air Compressor | ✓ | |

| Treated Water Recycling for Saturator | o | |

| Coagulation, flocculation reaction device | o | |

| Chemical powder dissolving dosing device | o | |

Food Industry Dissolved air flotation Details

- DAF has been successfully applied to the treatment of process and wastewater,water in many industries, including:

- Food industry

- Beverage industry

- Municipal sewage treatment

- Industrial wastewater treatment

- Recycling/Recovery of useful materials

- Water treatment

Application of air flotation

- Solids separation upstream of secondary processes such as:

- Oxidation Ditches

- Sequencing Batch Reactors

- Biological Aerated Filters

- Dissolved Air Flotation -Moving Bed Bio Reactors -Membrane Bio Reactors Primary treatment for new plants Grit removal after a coarse screen

- Increase primary or secondary process capacity

- Plant expansion where land is expensive or unavailable

- Dig-free, concrete-free solution for mountainous or earthquake-prone areas

- Combined sewer overflow (CSO) treatment

- Stormwater treatment

Food Industry Dissolved Air Flotation Cost-Effective

Our packaged DAF plants are pre-assembled and pre-tested in our controlled facility, often saving 50 percent or more over in-situ construction. They can also be integrated into pre-engineered building systems for increased savings and reduced schedule. Their small footprint also reduces building costs.

Simplicity

Our DAF plants are quiet, simple and easy-to-operate with minimal operator input. They are also supplied complete with chemical dosing, water quality instrumentation, automatic controls and monitoring systems customized to meet local needs.

Food Industry Dissolved Air Flotation Standard Features

- Adjustable effluent weir troughs

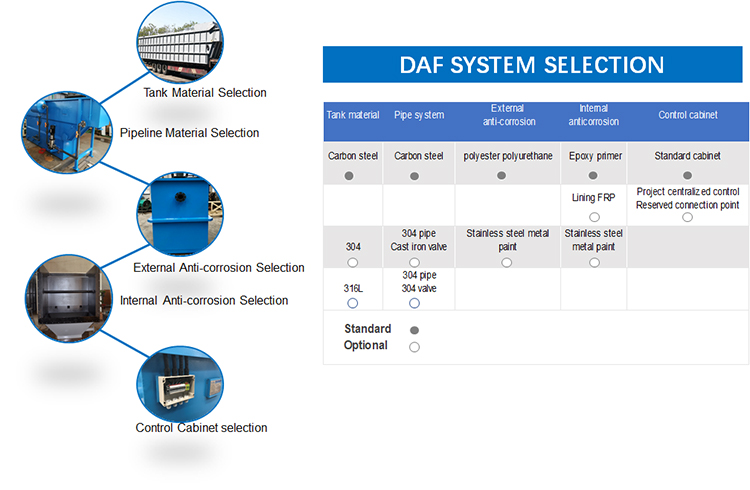

- Epoxy coated carbon steel tank

- Factory tested

- Seamlessly integrates with other Hydro-Flo offered wastewater products

- Stand alone operation

- Standard units can be manufactured for flows from 5 gpm to 3500 gpm and above, in a single above grade tank

- Structural steel support legs