Description

Static Inline Mixers

DAGYEE produces a complete line of custom stainless steel static mixers made from industrial grade schedules 10 through 40 pipe, in sizes ranging from 3/8"- 60" diameter.

All stainless steel metal static mixers are custom designed for each application.

DAGYEE stocks all of the raw materials for the mixer line and can produce a flanged industrial mixer in as little as 1-2 days, if needed.

Standard materials of construction include carbon steel, 304L and 316L stainless steel. Other higher alloys are available upon request for inline static mixers.

How Does A Static Mixer Work?

The mixing elements or fins induce turbulent flow in the mixer housing which mixes chemicals added either ahead of the mixer or through an injection port on the mixer housing. The process media will be mixed 95% within 3D (pipe diameter) of the mixer outlet, this is called the CoV or Coefficient of Variation.

Static mixers are aimed at 0.5 or 95% mixing at 3D (pipe diameter) of the mixer outlet.

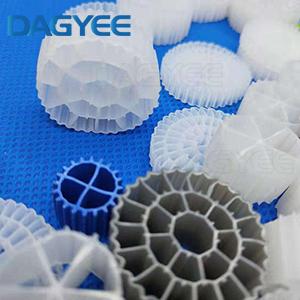

There is no typical static mixer design, a variety of designs are available to suit specific applications.

Helical coil mixers for the chemical pharmaceutical and food industries.

Fin mixers for the water industry - Fin mixers The mixing elements (foils) of the mixer are mounted on the walls of the mixer housing and are so-called open designs, which means that they are less likely to clog, they The pressure drop is lower than that of a helical coil mixer.

SK Series Model

|

Model |

Dg(mm) |

dh(mm) |

Q(m3/h) |

|

SK-5/10 |

10 |

5 |

0.15-0.3 |

|

SK-7.5/15 |

15 |

7.5 |

0.3-0.6 |

|

SK-10/20 |

20 |

10 |

0.6-1.2 |

|

SK-12.5/25 |

25 |

12.5 |

0.9-1.8 |

|

SK-16/32 |

32 |

16 |

1.4-3.2 |

|

SK-20/40 |

40 |

20 |

2.2-4.5 |

|

SK-25/50 |

50 |

25 |

3.5-7.0 |

|

SK-32.5/65 |

65 |

32.5 |

5.9-12 |

|

SK-40/80 |

80 |

40 |

9-18 |

|

SK-50/100 |

100 |

100 |

14-28 |

|

SK-62.5/125 |

125 |

125 |

22-44 |

|

SK-75/150 |

150 |

150 |

31-64 |

|

SK-100/200 |

200 |

200 |

56-110 |

|

SK-125/250 |

250 |

250 |

88-177 |

|

SK-150/300 |

300 |

300 |

127-255 |

|

SK-175/350 |

350 |

350 |

173-346 |

|

SK-200/400 |

400 |

400 |

226-452 |

|

SK-250/500 |

500 |

500 |

353-706 |

Benefits of Static Mixer

Maintenance-Free

Static Mixers are built to last using industrial grade materials specifically tailored to your application.

Low-Cost

Static Mixers are a low-cost alternative to traditional tank mixers both at purchase and during the mixer's lifetime. There are no running costs associated with operating Static Mixer on top of running your existing pipeline.

Low Energy Requirements

Because static mixers are motionless by design, all the energy required to provide a perfect blend is provided by the energy of the flow stream.

No Moving Parts

Unlike traditional mixers, static mixers remain motionless during the mixing process.

Custom-Designed for Your Application

Static mixers can be custom-tailored to fit your requirements.

Quick Delivery

Maintains complete control over its production process. All static mixers are built in-house at Koflo's manufacturing facility outside Chicago and can be manufactured to meet your project schedule.

Typical Applications

Chemical blending

Water treatment

Crude oil blending

Custody transfer

PH control

Liquid/vapor contacting

Produced Water Treatment

Desalination Biofuel blending and catalyst addition