Description

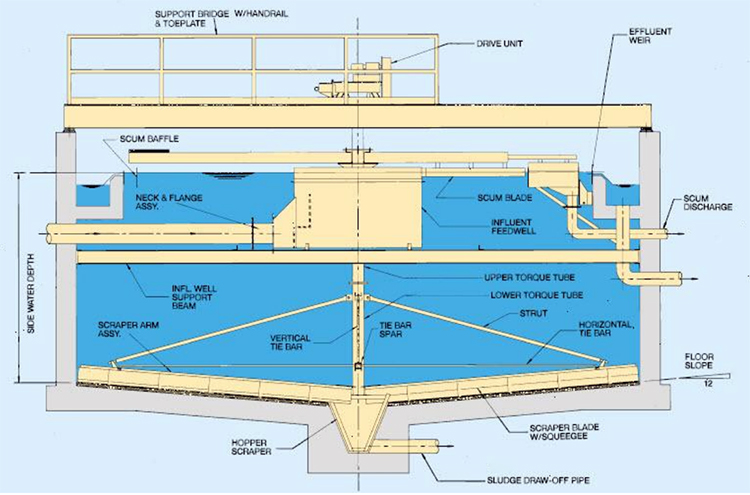

Gravity Sludge Thickener Bridge Mounted Waste Water Treatment

Selection steps

Use occasion

The central drive suspended mud scraper (thickening) machine is generally divided into primary sedimentation tank, secondary sedimentation tank or sludge thickening tank according to the design requirements.Model selection

Check whether the center-side drive suspended mud scraper (thickener) meets the design requirements according to the design load and use occasion.

Pool size

The size of the pool is determined according to the water volume and residence time in the design. The general process calculation has been determined. For example, if the pool diameter is 10m and the pool depth is 4m, a center-side drive suspended mud scraper (thickener) with a diameter of 10m is selected. The slope of the pool bottom also needs to be provided, and the speed can be designed according to the peripheral linear speed provided by the user, so it is best to provide civil engineering drawings when selecting and pricing.

| Model | DXG-10 |

| Pool diameter m | 10 |

| Water depth m | 3.6-4.4 |

| Pool depth m | 4-4.8 |

| Peripheral linear speed m/min | 1-2 |

| Drive power kw | 0.55 |

| Motor brand | SEW /NORD /GUOMAO |

| Material | Carbon steel bridge frame&transmission mechanism |

| Wetted material | SUS304/SUS316L |

Features

- Robust construction

- Self-diluting feedwell

- Enhanced polymer injection systems

- Cage and shaft lifting

Advantages

- Can develop high torque in compact units.

- Torque tube is generally more economical than a torque cage in smaller units.

- Can be installed in concrete or steel tank configurations. Generally most economical in tanks less than 50’ in diameter.

- Generally the most economical way to provide lifting of rake arms under severe torque loads.

- Lifting device option allows for heavy sludge loading

Applications

- Grind

- Thickening

- Concentrate

- Tailings

- Leach thickening

- CCD Circuits

- Acid mine drainage