Description

Lamella Separator Description

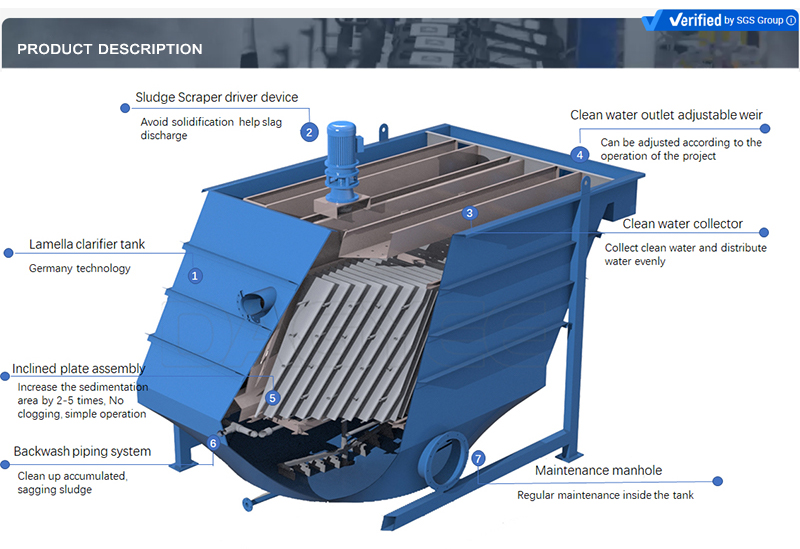

lamella clarifier is fitted with a plate pack to maximise the effective settling area of the unit and a conical sludge hopper in a small footprint. Lamella clarifiers are ideal for applications where the solid loading is variable and solid sizing is fine. Lamella Clarifiers are considered to be one of the best options for pre-treatment ahead of more sophisticated treatment technologies because of their ability to remove a significant solids loading. The MAK Water Lamella Clarifier can be integrated into a treatment process or as a stand-alone unit. Typical applications are for separation of grit or metal removal or any other application where the solids have a specific gravity >1.0.

Available options

•Flash mixing/flocculation tank with agitator

•Full glass steel or stainless steel structure

•Concrete tank design

•Special coatings and plates

•Integrated mechanical sludge thickener

•Overhaul platforms and ladders

•In-house laboratory analysis to optimize equipment

•Drinking water design

•Gasket and removable cover

•Automatic desilting

•Instrumentation and control

•Chemical feed equipment

•Sludge treatment and dewatering

•Pilot size units for field testing

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model |

Capacities (m3/h) |

Piping Connections() | Physical Dimensions(m) | |||||

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC- | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC- | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC- | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC- | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC- | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC- | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC- | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC- | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC- | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC- | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC- | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

Lamella Separator Advantages

Unit is Completely Assembled

Low Installation

Conservative Design 0.2 GPM/Ft2

Completely Automatic, Gravity in Gravity Out

Reduced Floor Space

Large Compartment Flocculation Tanks with Mixer for Extra Retention Time (approximately 50-60 minutes)

Lamella Separator Applications

Water following physical-chemical treatment.

Tailings in mining and metallurgical beneficiation.

Solutions from gold leaching processes.

Wet scrubbing effluents.

Effluent treatment in pulp and paper mills.

Filter backwash.