Description

Internally Rotary Drum Screen Description

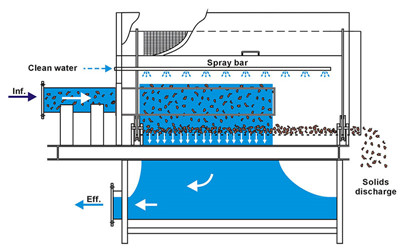

The internal feed rotary screen operates very little. Influent water enters through the inlet and flows into the headbox. The headbox is filled with water and the inlet overflows onto the weir and contacts the sides of the rotating cylinder screen. When the incoming water hits the rotating screen, the solids are trapped in the cylinder and the liquid enters the process through the screen or continues to be processed. A splitter on the cylinder moves the solid along the length of the screen for discharge. The device is equipped with spray bars head to clean the screen.

Reliable fine screening with maximum separation efficiency,Operating reliability for membrane bioreactors,Max retention of fibres and hair,Max COD / BOD5 reduction rates.

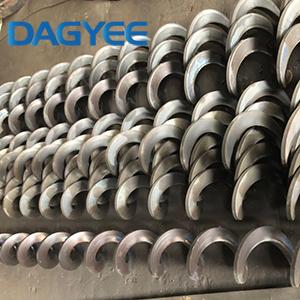

Rotating Drum Screen is composed of drum screen, support roller unit, drive mechanism unit, backwash cleaning system, discharge mechanism, cover plate assembly, maintenance door, frame and filtrate collection hopper.

Internally Rotary Drum Screen Model

|

DIRD

Model

|

Drum size | Physical Dimensions(mm) | Power |

Weight

(Kg)

|

Capacities(m3/h) | Sludge height | ||||

| mm | L | W | H | KW | 1mm | 2mm | 3mm | mm | ||

| IRD6-900 | Ø600x900 | 1900 | 1350 | 1700 | 0.55 | 630 | 15 | 25 | 30 | 500 |

| IRD6-1200 | Ø600x1200 | 2200 | 1350 | 1700 | 0.55 | 820 | 30 | 50 | 60 | 500 |

| IRD6-1500 | Ø600x1500 | 2500 | 1350 | 1700 | 0.75 | 1000 | 45 | 70 | 85 | 500 |

| IRD6-1800 | Ø600x1800 | 2800 | 1350 | 1700 | 0.75 | 1160 | 60 | 100 | 120 | 500 |

| IRD6-2100 | Ø600x2100 | 3100 | 1350 | 1700 | 1.1 | 1300 | 80 | 135 | 170 | 500 |

| IRD9-1200 | Ø900x1200 | 2300 | 1600 | 2200 | 1.1 | 1200 | 40 | 70 | 85 | 600 |

| IRD9-1800 | Ø900x1800 | 2900 | 1600 | 2200 | 1.1 | 1470 | 80 | 135 | 170 | 600 |

| IRD9-2500 | Ø900x2500 | 3600 | 1600 | 2200 | 1.5 | 1800 | 120 | 200 | 250 | 600 |

| IRD9-3000 | Ø900x3000 | 4100 | 1600 | 2200 | 1.5 | 2100 | 160 | 270 | 350 | 600 |

Internally Rotary Drum Screen Feature

High throughput capacity – maximum separation

Efficiency

Easy maintenance

Low operation costs

Low life-cycle costs

Optional high pressure cleaning reduces maintenance requirements

Various possible applications

Maximum corrosion protection through stainless steel

Design and acid treatment in a pickling bath

Internally Rotary Drum Screen Application

Industrial and municipal applications

Primary and secondary treatment stage

Protection of membrane plants

Replacement for primary settlement tank

Load reduction in the biological treatment system

Through reduction of COD / BOD/ AFS

Screening in the inlet to power plants

Treatment of cooling water circuits

Brewery wastewater

River and sea outfall

Surface and river water screening