Description

Multi-Disc Sludge Dewatering Screw Press Machine

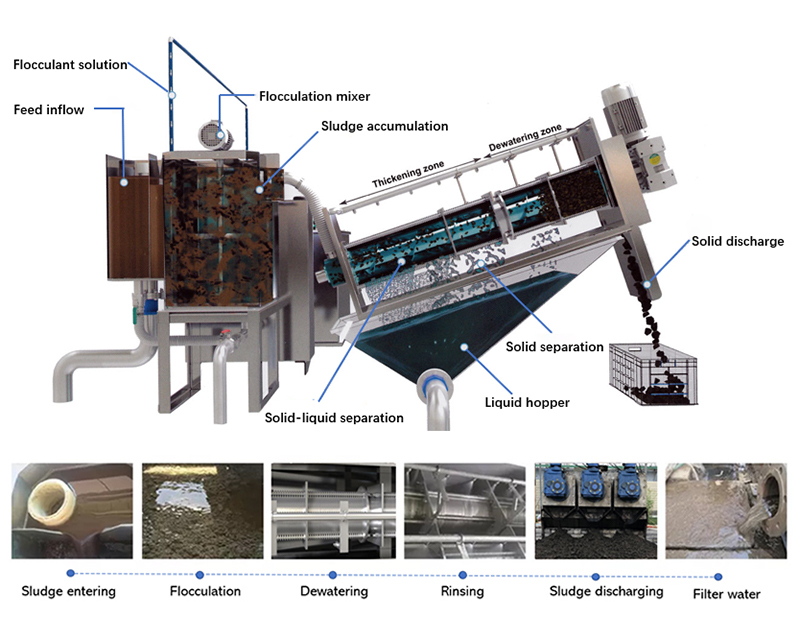

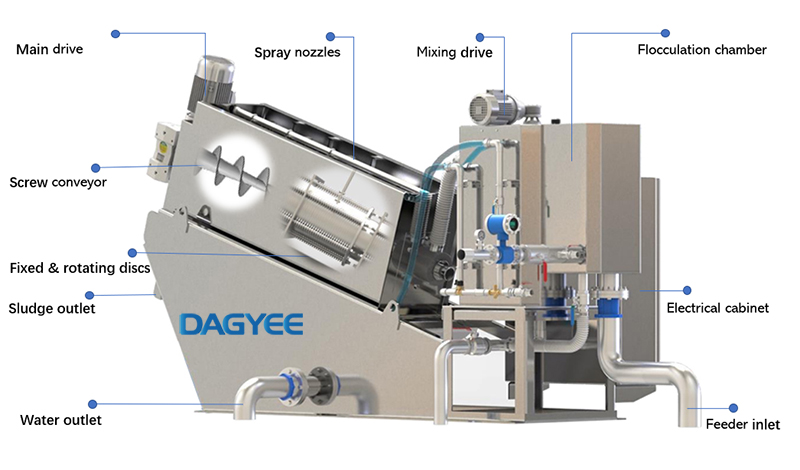

DAGYEE screw press sludge dewatering machine is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation.

DAGYEE dewatering screw press is composed of fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device, and liquid collecting tank. GN dewatering screw press is with automatic control technology, which can realize the flocculation fully automatic operation, and continuously complete the sludge thickening and squeezing, finally return or discharge the collected filtrate liquid.DAGYEE screw press dewatering machine is widely used in sewage treatment projects of municipal, aquaculture, food, starch, oil, pharmaceutical, chemical, paper, leather and other industries.

•Sludge can be dewatered under aerobic conditions to avoid phosphorus release from anaerobic sludge dewatering.

•Suitable for wide range sludge dewatering and can be used for oily sludge treatment.

•Operating continuously and automatically, not easy to block.

•Low investment and operation cost, no secondary pollution.

•Energy saving and environmental friendly, compact design with small footprint.

Product Specifications

| Model | Screw Diameter mm | Screw Nos. |

Screw Power KW |

Flushing Water L/H |

Weight KG |

| DL-101 | 100 | 1 | 0.2 | 24 | 220 |

| DL-201 | 200 | 1 | 0.4 | 32 | 420 |

| DL-202 | 202 | 2 | 0.8 | 64 | 550 |

| DL-301 | 301 | 1 | 0.8 | 40 | 900 |

| DL-302 | 302 | 2 | 1.2 | 80 | 1400 |

| DL-303 | 303 | 3 | 1.95 | 120 | 1900 |

| DL-401 | 401 | 1 | 3 | 80 | 2200 |

| DL-402 | 402 | 2 | 4.5 | 160 | 3500 |

| DL-403 | 403 | 3 | 6.7 | 240 | 5500 |

| DL-404 | 404 | 4 | 8.9 | 320 | 7000 |

|

Model |

DS Capacity(kg/h) |

Capacity for Sludge with Different Concerntration (m3/h) |

||||

| 10000mg/L |

20000mg/L |

30000mg/L |

40000mg/L |

50000mg/L |

||

| DL-101 | 5~7 | ~0.5 |

~0.25 |

~0.2 |

~0.15 |

~0.14 |

| DL-201 | 15~20 |

~1.5 |

~0.75 |

~0.6 |

~0.5 |

~0.4 |

|

DL-202 |

30~40 | ~3 |

~1.5 |

~1.2 |

~1 |

~0.8 |

|

DL-301 |

50~70 | ~5 |

~2.5 |

~2 |

~1.5 |

~1.4 |

|

DL-302 |

100~140 | ~10 |

~5 |

~4 |

~3 |

~2.8 |

|

DL-303 |

150~210 | ~15 |

~7.5 |

~6 |

~4.5 |

~4.2 |

|

DL-401 |

130~160 | ~13 |

~6.5 |

~5 |

~4 |

~3.2 |

|

DL-402 |

260~320 | ~26 |

~13 |

~10 |

~8 |

~6.4 |

|

DL-403 |

390~480 | ~39 |

~19.5 |

~15 |

~12 |

~9.6 |

|

DL-404 |

520~640 | ~52 |

~26 |

~20 |

~16 |

~12.8 |

Working Principle

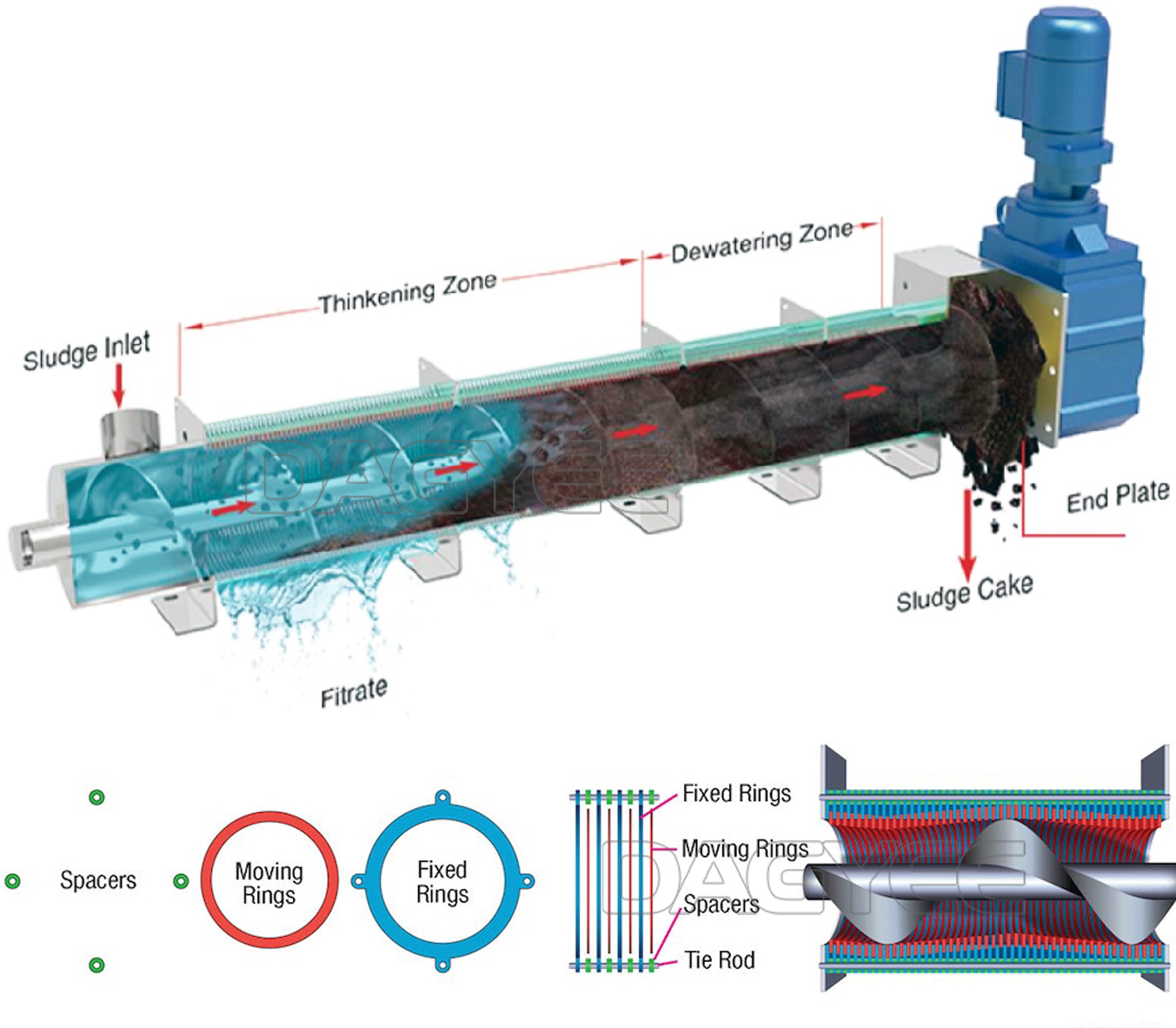

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity;

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce;

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.