Description

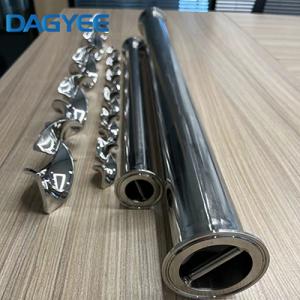

Screw Press Dehydrator

DAGYEE Multi-disc screw press dehydrators can cope up with a wide range of sludge concentrations from 0.2% to 10%, and also stably can dewater sludge that has high oil content.

The main purpose of Sludge dewatering machine is to minimize the handling and disposal. Sludge dewatering press is the most cost effective method of dewatering, and hence helps to sustain the environmental objectives of company.

Basically, both the public & private sectors are required to dispose the sludge which is approved by industries. Sludge dewatering is totally focused on the reducing weight as well as volume of sludge & also on cost & transportation services.

First step of Sludge dewatering is removing water from it so by removing water it will impact on reducing volume & weight of sludge.

Screw Press Dehydrator Features

- Automatic operation

- High quality and Reliability

- Continuous functioning

- Quick and easy installation

- Low energy consumption

- Innovative washing System

- Dewatering and discharge in one equipment

- Manufactured in Stainless Steel AISI 304 and 316(L)

- Welding pickled and passivated

- Easy removable covers for hygienic inspection

- Odour and Insects containing covers

- Low and easy maintenance

Screw Press Dehydrator Technical Table

| Model | DL202 |

| DS capacity kg/h | 18--30 kg/h |

| Sludge capacity m3/h(2-50g/L) | 0.6-9 |

| Spiral diameter mm | ¢200*2 |

| Discharge Distance mm | 350 |

| Size L*W*H mm | 2500*935*1270 |

| Net.Kg | 470 |

| Run Kg | 730 |

| Power Kw | 1.11 |

| Washing Q L/h | 64 |

Screw Press Dehydrator Application

- Simple arrangement

- Low Power Consumption

- Simple and short start-up and shut down procedures

- Continuous operation,hence continuous output can be obtained

- Process can be automized

- Only electricity and water supply for cleaning is required, and that too in less amount

- For a multi-channel machine, one or more channels may be removed for maintenance purposes, while the machine with the remaining channels may still be operated

- No clogging. Cleaning is automized and is easy

- Long life of discs

- No external lubrication system is required

- Flocculator built in the Screw press