Description

Externally Fed Drum Screens Description

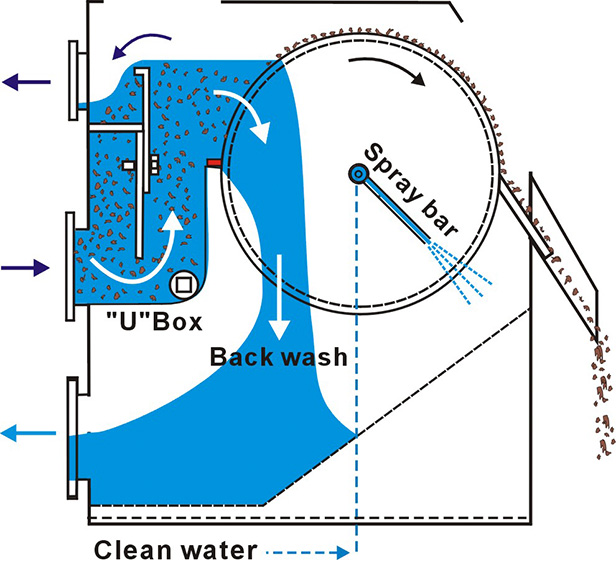

The process water or wastewater enters the screen via the headbox, overflowing onto the wedgewire screen drum where solids are effectively separated.The separated solids are then transported through the wedge-wire screen drum to the solids scraper blade the continuous gentle rotation of the screen drum. Screened solids are then dropped into a dumpster,screening wash press, compactor or conveyor. The rotary screening drum is driven by a side-mounted geared motor. An internal water spraying system is integrated into the screening drum.

Externally Fed Drum Screens How does it work?

The DRUM SCREEN executes fine micro-screening and is installed upstream of small and medium-sized purification plants. The flow of the suspension for screening meets the surface of the rotary screen perpendicular to the direction of the hole between the bars. While the filtered liquid passes through the holes of the screen and is discharged into a tank under the cylinder, the solids are trapped on the surface of the same screen and are drawn by rolling friction to a spillway blade that diverts them to a special container. The bars of the cylinder are wedge-shaped, permitting the uninterrupted flow of hydraulic pressure and minimizing the risk of solids sticking and causing obstruction.

Externally Fed Drum Screens Model

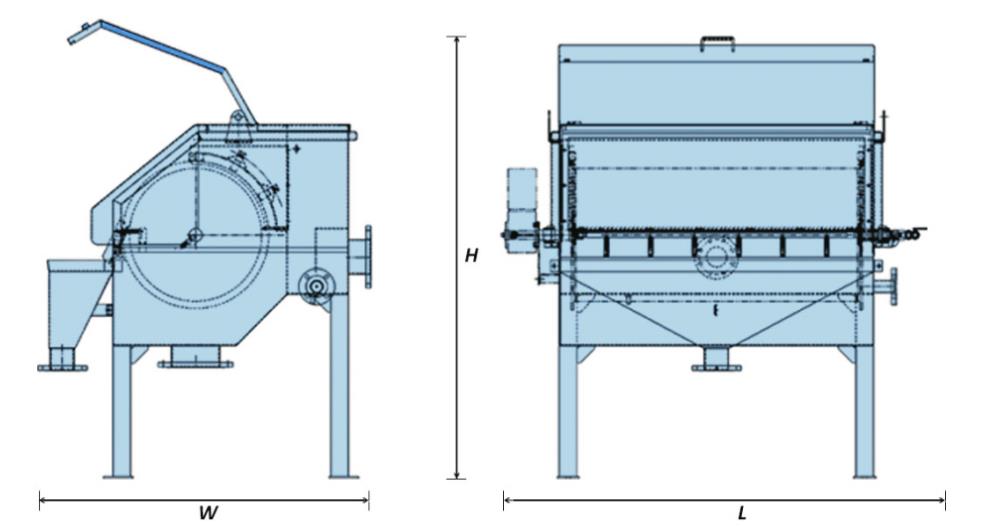

| Technical Table | ||||||||||

|

DDS Model |

Drum size | Physical Dimensions(m) | Power |

Weight (Kg) |

Capacities(m3/h) | Sludge height | ||||

| mm | L | W | H | KW | 1mm | 2mm | 3mm | mm | ||

| IRD6-900 | Ø600x900 | 1900 | 1350 | 1700 | 0.55 | 630 | 15 | 25 | 30 | 500 |

| IRD6-1200 | Ø600x1200 | 2200 | 1350 | 1700 | 0.55 | 820 | 30 | 50 | 60 | 500 |

| IRD6-1500 | Ø600x1500 | 2500 | 1350 | 1700 | 0.75 | 1000 | 45 | 70 | 85 | 500 |

| IRD6-1800 | Ø600x1800 | 2800 | 1350 | 1700 | 0.75 | 1160 | 60 | 100 | 120 | 500 |

| IRD6-2100 | Ø600x2100 | 3100 | 1350 | 1700 | 1.1 | 1300 | 80 | 135 | 170 | 500 |

| IRD9-1200 | Ø900x1200 | 2300 | 1600 | 2200 | 1.1 | 1200 | 40 | 70 | 85 | 600 |

| IRD9-1800 | Ø900x1800 | 2900 | 1600 | 2200 | 1.1 | 1470 | 80 | 135 | 170 | 600 |

| IRD9-2500 | Ø900x2500 | 3600 | 1600 | 2200 | 1.5 | 1800 | 120 | 200 | 250 | 600 |

| IRD9-3000 | Ø900x3000 | 4100 | 1600 | 2200 | 1.5 | 2100 | 160 | 270 | 350 | 600 |

Externally Fed Drum Screens Feature

sewage treatment plants

vegetable, fruit and potato processing industry

sugar industry

meat and poultry processing

fish and shellfish processing industry

brewing, malting and beverage industry

horticulture industry

Industrial process water

zoos

textile industry / laundries

paper and pulp industry

tanneries

waste recycling industry

bioenergy industry

drinking water plants, etc.

exhaust gas cleaning

Rotary drum screen water treatment Application

sewage treatment plants

vegetable, fruit and potato processing industry

sugar industry

meat and poultry processing

fish and shellfish processing industry

brewing, malting and beverage industry

horticulture industry

Industrial process water

zoos

textile industry / laundries

paper and pulp industry

tanneries

waste recycling industry

bioenergy industry

drinking water plants, etc.

exhaust gas cleaning