Description

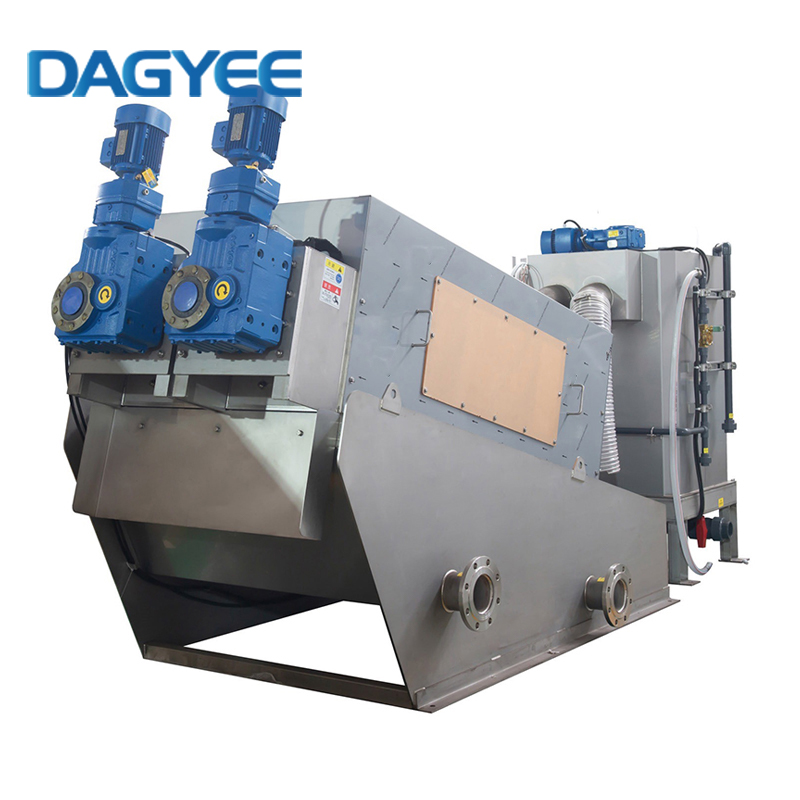

Screw Type Dehydrator Press Machine

Basically, both the public & private sectors are required to dispose the sludge which is approved by industries. Sludge dewatering is totally focused on the reducing weight as well as volume of sludge & also on cost & transportation services. First step of Sludge dewatering is removing water from it so by removing water it will impact on reducing volume & weight of sludge.

- No secondary pollution

- The screw shaft rotational speed about 2~3r/min, no vibration and noise is very small .

- Only need a small amount of water for self-cleaning, no secondary water pollution.

- Sludge runs at a slow operating condition. The smell does not spread.

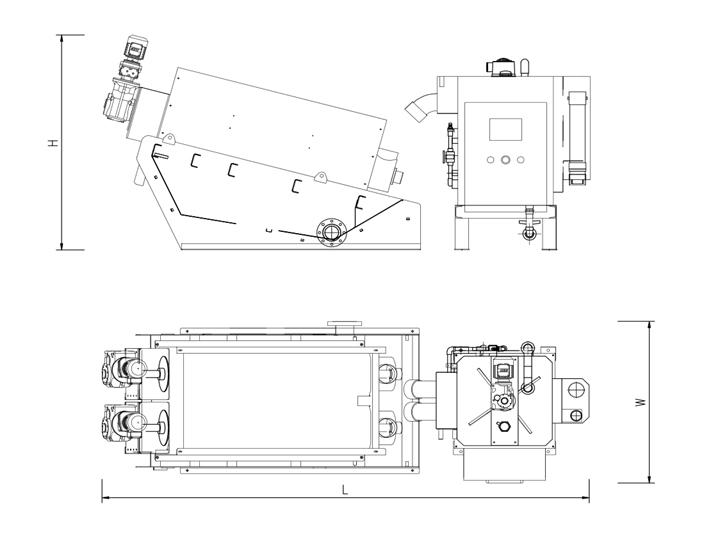

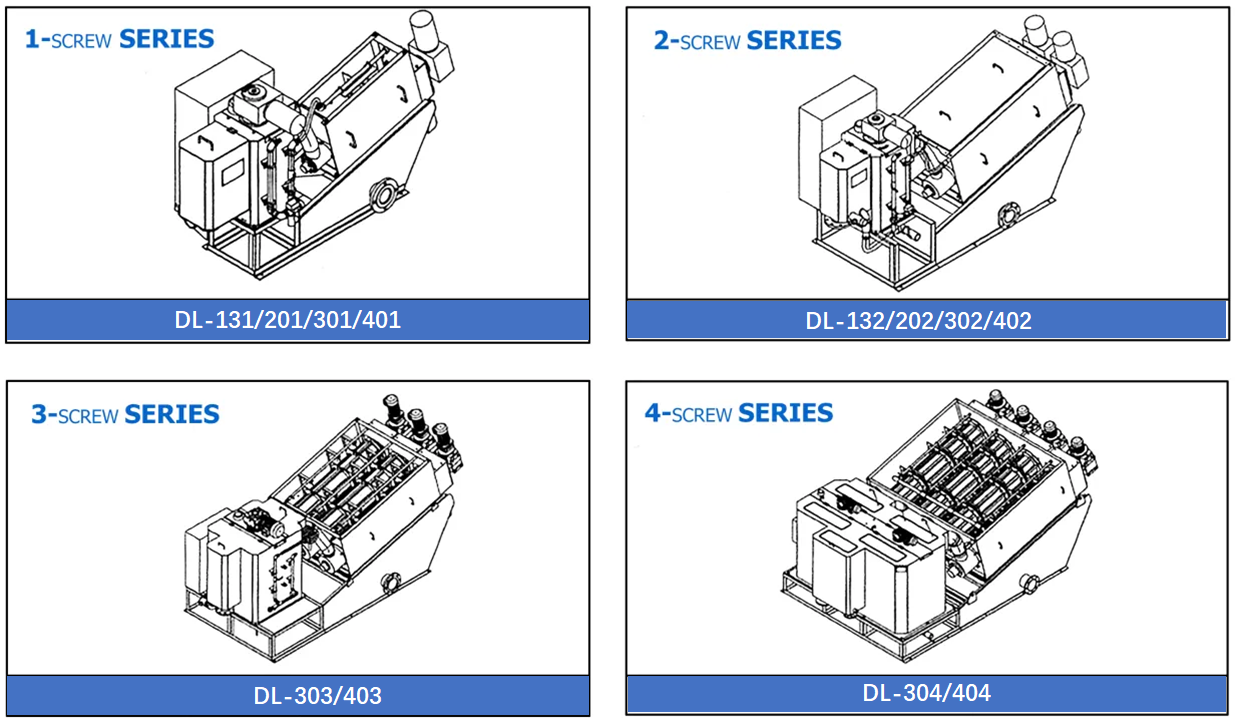

Product Specifications

| Model | Screw Diameter mm | Screw Nos. |

Screw Power KW |

Flushing Water L/H |

Weight KG |

| DL-101 | 100 | 1 | 0.2 | 24 | 220 |

| DL-201 | 200 | 1 | 0.4 | 32 | 420 |

| DL-202 | 202 | 2 | 0.8 | 64 | 550 |

| DL-301 | 301 | 1 | 0.8 | 40 | 900 |

| DL-302 | 302 | 2 | 1.2 | 80 | 1400 |

| DL-303 | 303 | 3 | 1.95 | 120 | 1900 |

| DL-401 | 401 | 1 | 3 | 80 | 2200 |

| DL-402 | 402 | 2 | 4.5 | 160 | 3500 |

| DL-403 | 403 | 3 | 6.7 | 240 | 5500 |

| DL-404 | 404 | 4 | 8.9 | 320 | 7000 |

|

Model |

DS Capacity(kg/h) |

Capacity for Sludge with Different Concerntration (m3/h) |

||||

| 10000mg/L |

20000mg/L |

30000mg/L |

40000mg/L |

50000mg/L |

||

| DL-101 | 5~7 | ~0.5 |

~0.25 |

~0.2 |

~0.15 |

~0.14 |

| DL-201 | 15~20 |

~1.5 |

~0.75 |

~0.6 |

~0.5 |

~0.4 |

|

DL-202 |

30~40 | ~3 |

~1.5 |

~1.2 |

~1 |

~0.8 |

|

DL-301 |

50~70 | ~5 |

~2.5 |

~2 |

~1.5 |

~1.4 |

|

DL-302 |

100~140 | ~10 |

~5 |

~4 |

~3 |

~2.8 |

|

DL-303 |

150~210 | ~15 |

~7.5 |

~6 |

~4.5 |

~4.2 |

|

DL-401 |

130~160 | ~13 |

~6.5 |

~5 |

~4 |

~3.2 |

|

DL-402 |

260~320 | ~26 |

~13 |

~10 |

~8 |

~6.4 |

|

DL-403 |

390~480 | ~39 |

~19.5 |

~15 |

~12 |

~9.6 |

|

DL-404 |

520~640 | ~52 |

~26 |

~20 |

~16 |

~12.8 |

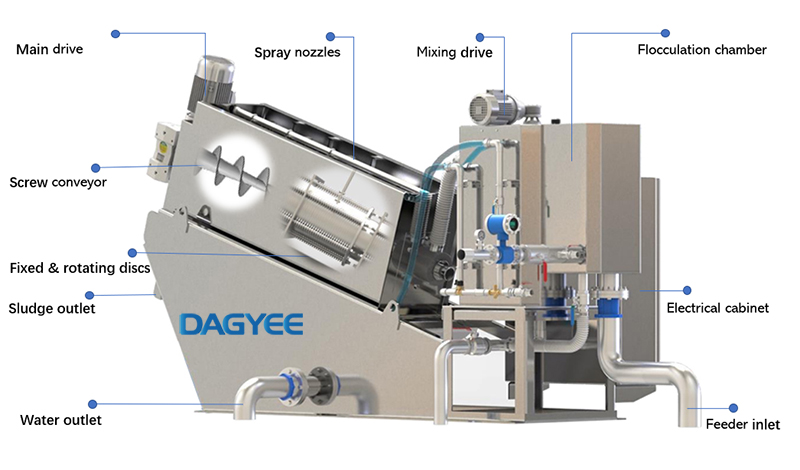

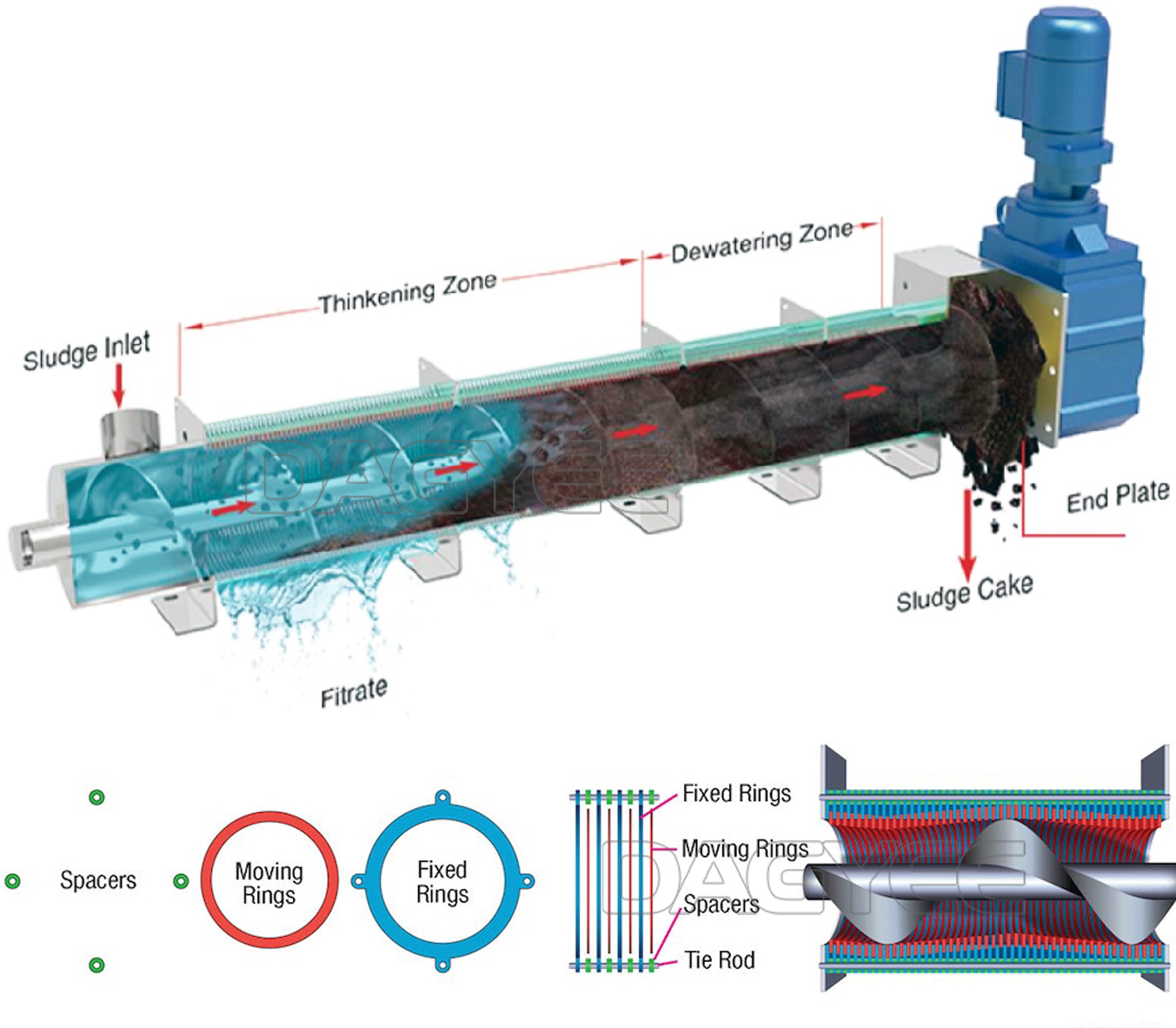

Working Principle

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity;

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce;

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.