Description

Externally Fed Drum Screen

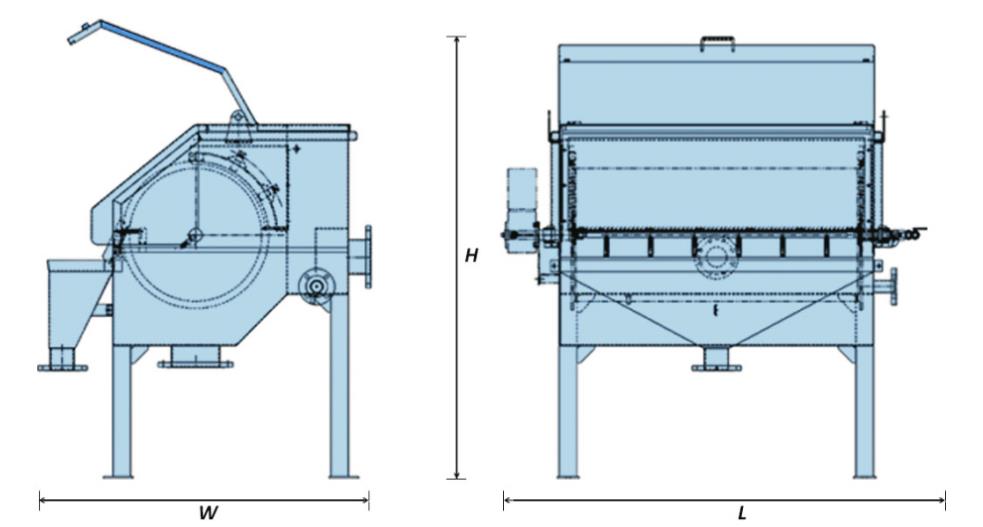

DDS (A) type Externally Fed Drum Screen is a kind of fine grid that can continuously and effectively screen suspended solids in water. The surface can be selected to suit the shape of the suspended matter in the water.

The maximum water flow of a single unit can reach 5000m3/h. It is also possible to configure the intelligent unit of the grid according to the quantity and variation of the suspended solids in the sewage to optimize the operating parameters and achieve energy saving.

This series of grilles is mainly used in fine filtration or industrial sieving process of sewage pretreatment. It can efficiently remove suspended solid particles or fibrous impurities in water, and greatly reduce the processing load of subsequent processes.

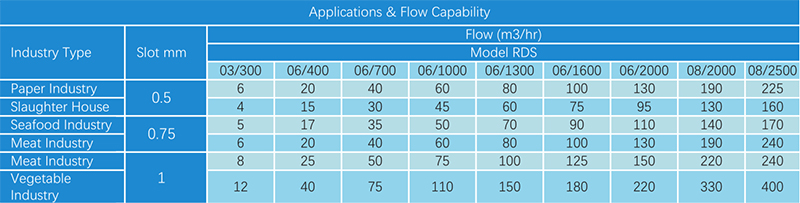

Rotating Drum Screen Technical

Externally Fed Drum Screen Advantage

Adopting pipeline connections, no complex concrete structures are required; The cost of civil construction and equipment is low, low energy consumption; Water -free components, convenient equipment maintenance and maintenance; Hydraulic easy process arrangement; Intelligent control, simple management, energy saving and efficient.

External Rotary Drum Screen Benefits

V-shaped wedge wire screen design

Built-in overflow protection

Separating and Self-Cleaning same step

Internal spray bar design

Wide range of industrial applications

Low capital and operation cost

Provide long years and trouble-free service

Automatic operation, requires little operator attention

External Rotary Drum Screen Application

Sewage treatment plants

Vegetable, fruit processing industry

Sugar industry

Meat and poultry processing

Fish and shellfish processing industry

Brewing, malting and beverage industry

Horticulture industry

Industrial process water

Textile industry & laundries

Paper and pulp industry

Exhaust gas cleaning

Waste recycling industry

Bioenergy industry

Drinking water plants