Drum Fine Screen Selection Instructions

Drum Fine Screen Selection Instructions

Drum screen there are two categories according to the water inlet method:

- External drum screen

- Internal drum screen

Drum screen working principle

The working principle of the drum screen : In simple terms,

the sewage passes through the filter screen to trap large solids and suspended

matter on the surface of the screen, and the filtered waste water is discharged

through the water outlet tank. Under normal circumstances, the particle size of

impurities in the water is relatively small, and the drum type mechanical grid

can be used for small particles such as hair. The grid space can be between

0.3-1mm.

The difference between internal water inlet and external

water inlet:

the internal water intake pipe directly enters the interior

of the drum, and the sewage passes through the inner surface of the screen and

the solids and suspended matter are intercepted by the filter, and then rotates

through the drum to the slag bucket.

Working principle of external water inlet: Waste water enters

the water collection tank and overflows to the surface of the drum screen

through overflow. The solid and suspended matter are intercepted by the filter

and scraped from the scraper to the slag bucket, and the filtered water passes

through the pores of the screen. Drain to the water tank.

Drum screen Composition

Drum-type fine grille is mainly used in

sewage treatment and industrial wastewater treatment projects to remove small

floating objects in the water. It is often used after the coarse grille. It is

mainly composed of reducer, screen, screw shaft, cleaning device, bracket, and

slag bucket. System composition:

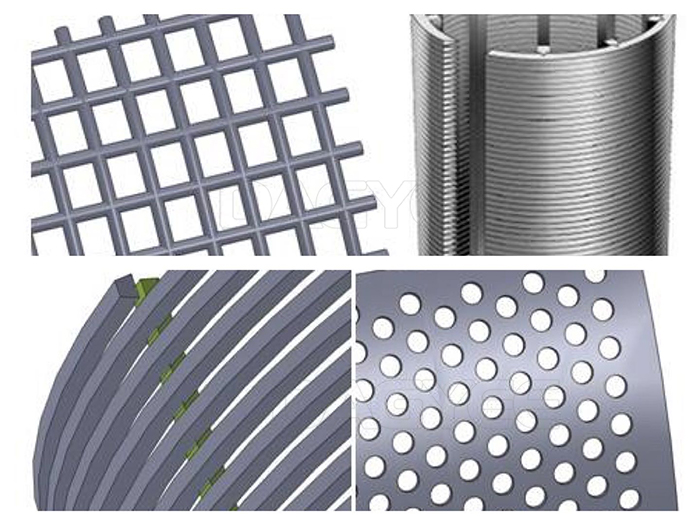

Usually, the external water inlet drum fine grid is limited by its structure, and the filter grid drum can only adopt the form of wedge-shaped spiral net. The inner water inlet drum fine grid filter grid drum can adopt different filter materials according to different filtering needs, such as: wedge-shaped spiral mesh, perforated plate mesh, stainless steel wire mesh, etc.

Drum Screen Applicable

- Drinking water

- Urban sewage treatment

- Beverage industry

- Textile industry

- Food processing industry papermaking wastewater

- Leather industry

- Slaughter industry

- Pharmaceutical Wastewater

- Petrochemical

Note: perforated mesh or stainless steel wire mesh for grid filter media, usually perforated mesh can be selected for pores above 2mm, and stainless steel wire mesh for those below 2mm. If the customer needs, the spiral wedge net can also be used.