Off-line cleaning methods and steps of reverse osmosis membrane elements

First, replace the membrane elements to be cleaned on the reverse osmosis system with spare membrane elements with excellent performance to ensure that the reverse osmosis system does not stop running and to ensure the continuous stability of the entire production process.

Performance test of reverse osmosis membrane element:

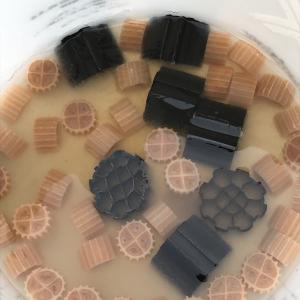

Identification of pollutants. First, make a preliminary judgment based on the analysis results, and then use special equipment and appliances for further verification to determine the specific pollutant types.

Test each membrane element individually for its performance indicators, including: desalination rate, water production, pressure difference, weight, etc., and record the desalination rate, water production and pressure difference before testing. Test conditions: meet different types of membrane manufacturers Provided standards.

Understand the current operating status of the system before cleaning the system;

Collect each parameter index of the reverse osmosis system and make the original record;

Judge the cleaning process based on the user's raw water analysis report, performance test results and system information learned;

The cleaned membrane elements will enter the test platform for testing and record. Those that do not meet the requirements will be sent back to the cleaning equipment for processing;

According to the analysis results, determine the required cleaning formula. When the contaminants on the RO membrane are determined, we can choose a series of formulas provided by the membrane manufacturer, and choose one or two more suitable formulas; or choose a special formula (when the RO membrane is contaminated by special contaminants, use ordinary The effect of the formula is not good, or from an economic point of view, the special formula is more economical). At present, there are many special agents for cleaning reverse osmosis membrane elements at home and abroad.

Use the above cleaning agents combined with physical treatment cleaning methods to conduct experimental cleaning on the special reverse osmosis cleaning equipment to select the appropriate cleaning formula and cleaning procedure;

Determine the cleaning method and treat all the above membrane elements;

Organize cleaning data and write a cleaning summary report.

In the pollution control of reverse osmosis, the most fundamental measures are the control of the design, manufacturing and installation process of the water treatment system with reverse osmosis as the core, the selection of various consumables of the reverse osmosis system, and the control of operation management level. A good grasp of these aspects plays a vital role in the safe and healthy operation of the reverse osmosis system.

Of course, when serious pollution occurs in the reverse osmosis system, the first measure to be taken must be to analyze the cause of the pollution, find a solution to the pollution, and clean the reverse osmosis system in the shortest time through an appropriate way, because with time The extension means the reduction of cleaning difficulty