Description

WHY CHOOSE SLUDGE SCREW DEWATERING

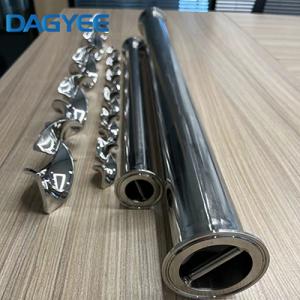

DAGYEE sludge dewatering spiral filter press for industrial wastewater treatment plants developed using dewatering technology

The principle of the same direction of power and water, thin-layer dewatering, proper pressure and extension of the sludge dewatering path. The new equipment is more advanced than the traditional dewatering equipment, easy to block, not suitable for low-concentration sludge and oily sludge, high consumption, difficult to operate, can eliminate these problems well, with higher efficiency and power saving effect.

Volume Reduction

No dewatering (0.5%) ,With Dewatering (20%)

High Efficient Presentation Of Following Process

Recycling Resources

WHAT IS SLUDGE SCREW PRESS DEWATERING

Dewatering screw press separate liquids from solids. It is a slow-moving device that can dewater sludge by gravity. Screw presses are used for materials that are difficult to dewater, including materials that are stacked together. Screw presses use a filtration system to separate liquids from solid materials. The liquid is collected as it flows through a screen or filter and can be reused.

DAGYEE SCREW PRESS provides unique, cost effective solution for dewatering of Industrial and Municipal Process Equipment Packages.

The device is designed to dewater the Primary Sludge and ƒor Secondary Sludge dewater sludge from a dry content of 0.8−4% to 15−20%.

DEWATERING KEY ISSUE

General characteristics affecting dehydration performance:

* Solid concentration* Biological characteristics of loading rate affecting dehydration performance

* Type of sludge (main, activated waste, mixture)

* Sludge treatment (digestion, heat, chemical)

* Fibrous materials or filamentous bacteria Volatile Chemical properties of suspended solids affecting drainage performance

* Nature of water in sludge (free, interstitial, combined)

* Phosphorus (PO4-P)

* Monovalent / divalent ion ratio

* pH

* Temperature

DAGYEE SLUDGE SCREW DEWATERING FEATURES

- Automatic operation

- High quality and Reliability

- Continuous functioning

- Quick and easy installation

- Low energy consumption

- Innovative washing System

- Dewatering and discharge in one equipment

- Manufactured in Stainless Steel AISI 304 and 316(L)

- Easy removable covers for hygienic inspection

- Low and easy maintenance