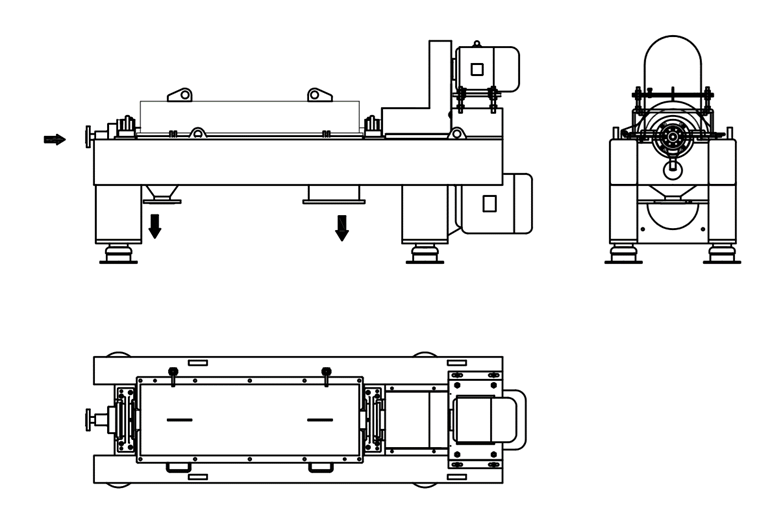

Description

2 Phase Decanter Centrifuges Description

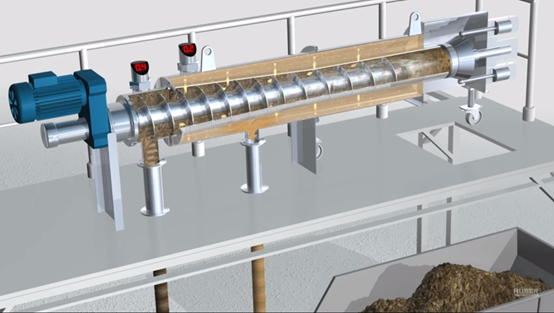

No high-speed rotating drum with a hole to install loser concentric spiral. both in a certain difference to the same rotational speed. The speed difference is generated by the diferential. Suspension by the introduction of spiral pipe feeding tube after the initial accelerated into drum. under the centrifugal force. heavier solid precipitation in the drum wall formed sediment layer pushed by the spiral bevel of the drum to further dehydration after serving small moutt. slag discharges; and the less liquid is formed by the inner-ring

reading overflow discharge.

2 Phase Decanter Centrifuges Model

| Model |

Drum diameter

mm

|

Length

mm

|

Maximum speed

rpm

|

Hightest separation

factor g

|

Mixture capacity

m3/h

|

Motor Power

Kw

|

| LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 | 11/5.5 |

| LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 | 18.5/5.5 |

| LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 | 22/7.5 |

| LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 | 22/7.5 |

| LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 | 22/7.5 |

| LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 | 30/7.5 |

| LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 | 30/7.5 |

| LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 | 45/15 |

| LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 | 55/18.5 |

| LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 | 55/90 |

| LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 | 75/90 |

| LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 | 90/132 |

| LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 | 90/132 |

| LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 | 132/200 |

2 Phase Decanter Centrifuges Technical

All contact parts can be made by SS304/SS316L/Duplex Steel 2205 Automatic adjustment of differential speed via VFD,Siemens PLC Spiral :

Surfacing welding tungsten carbide grinding

Two motor drive

Approximately 80 to 90% of the oil is recovered

Low labor costs due to continuous and automatic operation

Highest g-force for higher solids output

Belts for both primary motor and secondary

NSK/SKF Bearing

2 Phase Decanter Centrifuges Features

Low noise, its vibration intensity is less than 4.5, and the running noise of the machine is less than 85dB (A);

High Speed up to 3600RPM & Variable Speed by frequency converter;

The main body of the decanter centrifuge made from stainless stee: SS304/SS316/Titanium Alloy;

The screw propeller made from stainless steel (SS304/SS316) protected by Tungsten carbide alloy or Ceramic;

Solids discharge stainless steel protected by high-chromium iron;

Solids Liquid separation system package available;

Germany FAG/SKF brand bearings;

Eletrical Components: SIEMENS/Schneider/ABB;

All the seals of the machine are imported , adopting the Taiwan TTK brand.

2 Phase Decanter Centrifuges Application

Paper sludge

Weather desulfurization sludge

Power plant sludge

Activated sludge

Ammonia sludge

Car wash sludge

Sludge drilling mud

Coal flotation waste

Cryolite flotation liquid