Description

WHAT IS LAMELLA CLARIFIER

Industrial Wastewater Lamella Plate Clarifier can be used in a series of industries such as mining and metal finishing. It can also be used to treat groundwater, industrial water and sand filter backwashing. lamella clarifier is very suitable for applications with variable solid loading and fine solid separation. It covers a small area and is more common in many industrial sites than traditional clarifiers.

HOW DOES LAMELLA CLARIFIER WORKS

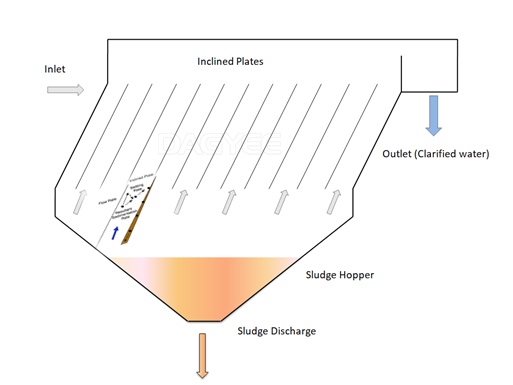

When using, you can choose to add coagulant. The method is to install inclined plate component with an inclination angle of 60 degrees above the suspended layer of sludge. Suspended solids in the raw water, solids or floc alum flowers formed by adding a coagulant are added to the surface area of the inclined plate Accumulate into a thin mud layer, rely on gravity to slide back to the suspended sludge layer, and then sink into the mud hopper. The sewage pipe is discharged into the sludge tank for further treatment or comprehensive utilization. The supernatant gradually rises to the drain of the water collection , which can be directly discharged or reused.

RANGE OF APPLIOCATION

- Mining

- Metal finishing

- Treat groundwater

-

Industrial process water

- Pre-treatment ahead of membrane filters

- Municipal wastewater

- TSS solids particulate removal

- Dissolved solids and metals precipitation

- Leachate clarification

- Cooling tower water clarification

- Surface raw water treatment

- Water recycling/reuse

- Backwash from sand filters

AVAILABLE DESIGNS

- Particle settling behavior (clarification layer)

-

Tube or plate spacing is 80 mm

-

Board length 1-2 m

-

The plate spacing is between 50° and 60°, which can be self-cleaned, and the lower spacing requires backwashing

-

Typical loading speed is 5 to 10 m/h

LAMELLA CLARIFIER EQUIPMENT SPECIFICATIONS

The flake clarifier can handle the highest feedwater concentration of 10000 mg/L grease and 3000 mg/L solids. The expected separation efficiency of a typical unit is:

Under standard operating conditions, 90-99% of free grease can be removed.

It can remove 20-40% of emulsified oil without chemical modification.

Adding chemical reagents can remove 50-99%.

The turbidity of the treated water is about 1-2 NTU