Description

Mechanical Fine Screen Description

The treatment of urban sewage has always been one of the issues that people are concerned about. No matter which city it is, the amount of sewage is relatively large, and the process of sewage treatment is also very difficult. Therefore, it is necessary to install and use advanced equipment to complete the sewage treatment work. It can clean the environment and provide people with a more comfortable and healthy living space. When treating sewage, the equipment used by people in the past was relatively simple, and most of the equipment products could not achieve the ideal work efficiency during operation due to the limitation of production technology. After the introduction of mesh grille equipment, this equipment was selected The number of product manufacturers began to increase, because the application of this treatment equipment can better solve the urban sewage work.

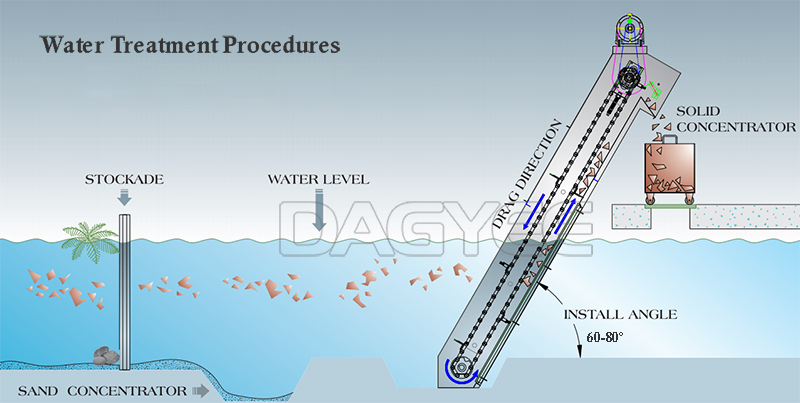

Mechanical Rake Screen is a solid-liquid separation device which has been widely used in municipal wastewater treatment plant,pre-treatment device for domestic effluents, municipal rainwater & sewage pump station. It is regarded as the ideal solid-liquid separation equipment in water treatment field.

Mechanical Fine Screen Composition

Parts of the fine grille of the inner inflow mesh plate frame;

Drive System;

Stencil System;

backwash system;

Division system and Electronic control system;

The geared motor drives the sprocket to rotate. The sprocket drives the mesh plate to rotate continuously; the sewage enters the grille from the water inlet, and passes through the mesh plate to overspeed. The water flows to the outside of the screen plate, and the dirt is left on the inner surface of the same plate. With the continuous rotation of the screen plate, it helps to the original part: the backwash system flushes the outside of the screen plate, and the dirt is washed to the receiving channel under the action of the flushing water. Feel free to check the flushing water from the well to the sewage outlet.

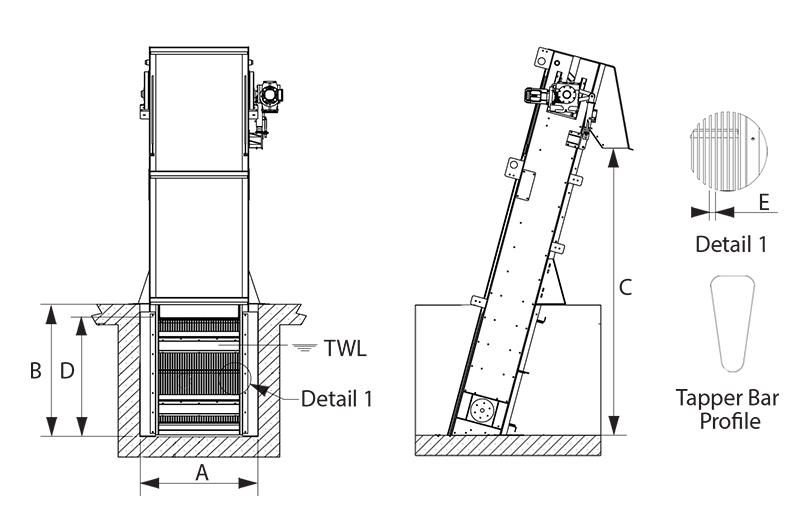

Mechanical Fine Screen Parameter

Grid width A(mm)

600-3000

Grid well width mm)

A+100

Effective filter width (mm)

A-150

Grid well depth H(mm)

1.5-4

Installation angle °

60-80

Mesh diameter (mm)

2 3 5 6 8 10

Running speed (m/min)

Less than 3

Main drive power (KW)

0.75-3

Cleaning power (KW)

0.37-0.75

Cleaning pressure (Mpa)

More than 0.3

Design maximum water level difference (m)

1.0

Capacity Mesh diameter with 3mm (m3/hr)

700

Capacity Mesh diameter with 4-6mm (m3/hr)

900

Capacity Mesh diameter with 7-10mm (m3/hr)

1200

Mechanical Fine Screen Advantage

Sewage flows in from the middle of the grille and flows out from both sides through the filter plate.

Compact structure, small footprint and large processing capacity, can adapt to the fluctuation of influent liquid level, small water head loss, high efficiency, high retention of filter residues, fibers and other substances, fully enclosed, light and light cover plate, easy to open and close, no filter residue material flow to the back of the grid phenomenon filtration The sealed connection between the plates is a proprietary technology that is not sensitive to gravel or grit filtration. The unique use of flushing rods and rotating brushes to automatically clean the filter plates.

Mechanical Fine Screen Options

Alternative screen types and sizes

Material 304 L / 316 L SS

Alternative voltage and frequency

Alternative degree of motor protection

Control panel

Mechanical Fine Screen Application

It is a high-efficiency fine grille decontamination equipment that combines pollution blocking and decontamination. It is suitable for large, medium and small pump stations as fine grilles to intercept and remove floating objects in the water, such as: weeds, paper, cigarette butts, melon seeds, fibers, hair, etc. This model has a high dirt capture rate , the effective implementation of the subsequent treatment process.