Coagulant and flocculant dispensing and dosing system (in water treatment system) operating procedures

Coagulant and flocculant dispensing and dosing system (in water treatment system) operating procedures

Functions of the dispensing and dosing system:

mainly provides the necessary coagulant for air flotation reaction and sludge conditioning, in order to strengthen the reaction effect and improve the treatment efficiency.

operation steps:

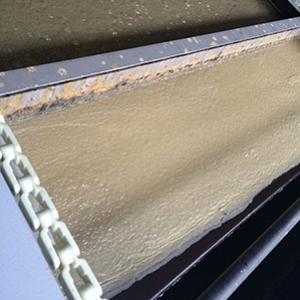

(1) PAC (Poly Aluminum Chloride) preparation and dosing

- Put tap water into 2/3 of the PAC reagent box, turn on the PAC mixer, add the required PAC evenly into the box, continue to add water while stirring, stop adding water when it reaches the 4/5 position of the medicine box, and continue stirring for 30 minutes. Can be added; the mass ratio of PAC dissolved medicine can be controlled at about 3-5% to ensure the stable and continuous reaction effect.

- Open the PAC dosing pump outlet reflux valve to prevent accidental closure of the remote dosing point valve from damaging the pump; at the same time, open the dosing pump outlet dosing valve, and then turn on the PAC dosing pump to do the medication. On-site response effects to adjust control;

- Stop dosing: When the entire PAC dosing point (mainly the air flotation reaction zone) needs to be stopped, press the PAC dosing pump stop button.

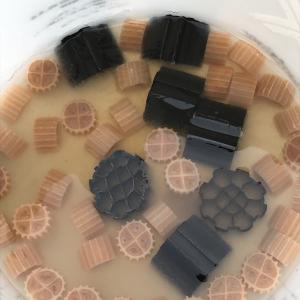

(2) PAM (polyacrylamide) preparation and dosing

- Put tap water into the 2/3 position of the PAM reagent box, turn on the PAM mixer, and at the same time, slowly and evenly sprinkle the required PAM into the dosing box, continue to add water while stirring, until the 4/5 position of the medicine box Stop adding water and continue stirring to completely dissolve PAM; PAM cannot be prepared and used immediately, and it needs to be hydrolyzed for more than a few hours to dosing better; the mass ratio of PAM dissolving drug can be controlled at about 0.1-0.2% to ensure consistent drug concentration and reaction The effect is stable and continuous.

- Open the PAM dosing pump outlet reflux valve to prevent accidental closure of the remote dosing point valve from damaging the pump; at the same time, open the dosing pump outlet dosing valve, and then turn on the PAM dosing pump to dosing. On-site response effects to adjust control;

- Stop dosing: When all PAM dosing points (mainly the air flotation reaction zone) do not need to dosing, press the PAM dosing pump stop button.