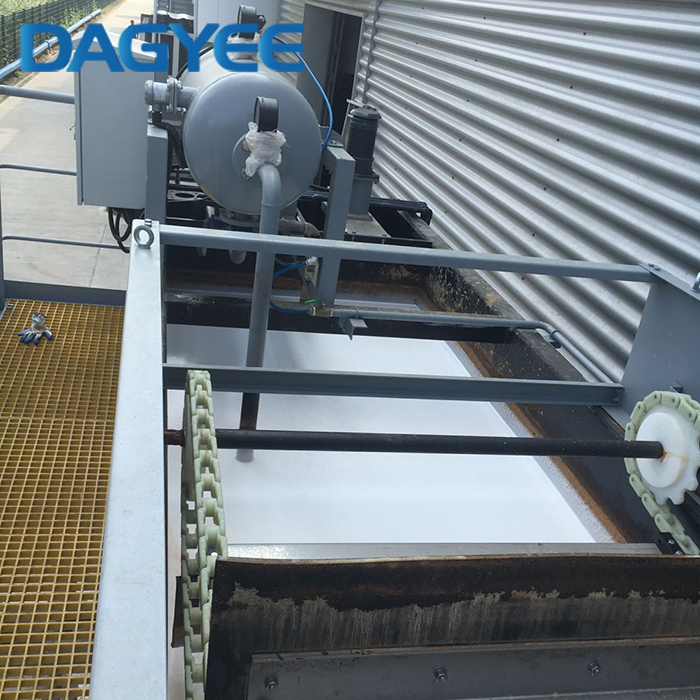

DAGYEE Dissolved air flotation commissioning matters needing attention

DAGYEE Dissolved air flotation commissioning matters needing attention

(1) Pay attention to the operation points and sequence of the three units of air flotation tank reaction, dissolved air and slag scraping. Do not start the machine for the first time, add chemicals, turn on the adjustment tank to lift the pump, adjust the dosage and effect, turn on the air float system, and float. Open the scraper after the slag is formed;

(2) The air intake valve must be closed when the dissolved air pump is started, and the dissolved air pump is strictly prohibited from running without water! In normal operation, the pressure range of the inlet vacuum gauge of the dissolved air pump should be controlled at 0.01-0.02MPa (negative pressure), and the outlet pressure of the dissolved air pump shall be controlled at 0.4-0.5MPa;

(3) The air flotation tank needs a long time (more than 3 days) due to maintenance and other conditions. The bottom sludge that may be stored in the air flotation tank is discharged into the sludge tank in time to prevent flocs from depositing for a long time and causing fouling. Block the flow channel; during normal operation, the bottom sludge is usually discharged once every half a month, and the operator must remember!